When Does DIY Hit Its Limit From Blinking LEDs to Reliable LoRa Networks

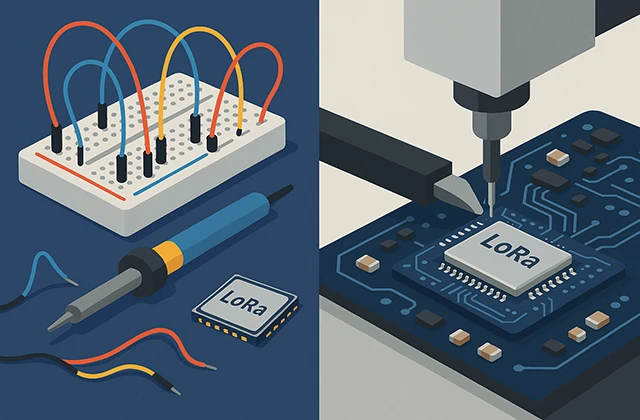

Remember that first thrill? The moment your code breathed life into silicon, making an LED blink exactly as you commanded? That spark ignites the journey for countless makers. We start with breadboards, tangled jumper wires, and the satisfying smell of solder. This hands-on, DIY approach is invaluable – it teaches fundamentals, fosters creativity, and offers complete control. But as ambitions grow, particularly when venturing into sophisticated technologies like LoRa, a critical question emerges: stick with the DIY path, or embrace the precision of professional manufacturing?

The Rewarding, Rugged Path of DIY

Building circuits by hand is an intimate process. You learn component by component, troubleshoot connection by connection. Perfboards and hand-etched PCBs are milestones, each completed project a testament to patience and skill. For simple prototypes or one-off gadgets, this is often perfectly sufficient. However, complexity introduces challenges. Tiny surface-mount components become fiddly nightmares. Ensuring signal integrity, especially for sensitive RF circuits like those needed for LoRa communication, demands precision that's hard to achieve consistently by hand. Reproducibility suffers, and scaling up? That often means hours upon hours of repetitive, error-prone soldering – time perhaps better spent refining your design or code, especially when dealing with intricate LoRa module integrations.

DIY vs. Pro

The Leap to Professional Precision: Enter PCBA

This is where professional Printed Circuit Board Assembly (PCBA) services shine. Imagine designing your circuit, exporting the files, and receiving perfectly manufactured boards with components flawlessly placed and soldered – including those minuscule LoRa modules. Professional manufacturing offers:

Reliability: Automated processes minimize human error, ensuring each board functions identically. This is crucial for applications like LoRaWAN sensor networks where dependability is paramount.

Speed & Scale: Need ten boards? A hundred? A thousand? PCBA services handle volume efficiently, freeing you to focus on the bigger picture.

Complexity Handling: Advanced equipment can handle tiny components (like 0201s or BGAs), multi-layer boards, and impedance control – essential for optimizing LoRa range and performance.

Professional Finish: Let's face it, a professionally assembled board simply looks and feels more robust and market-ready.

The transition isn't just about convenience; it's often a necessity for projects involving technologies like LoRa, where precise layout and assembly directly impact RF performance and overall reliability. Getting that LoRa signal through clearly and consistently often benefits immensely from professional manufacturing techniques.

Bridging the Gap: Opportunities Like Elecrow's

Making the jump from DIY to professional PCBA can seem daunting, sometimes involving costs or minimum order quantities. That's why initiatives like Elecrow's LoRa Modules Giveaway and PCB Assembly Sponsorship (as seen on their blog) are so valuable. They offer makers a fantastic opportunity to experience the benefits firsthand. Getting access to free LoRa modules or having your LoRa-based PCB project professionally assembled can be the perfect catalyst to test the waters. It allows you to compare the results, understand the process, and see how professional services can elevate your LoRa projects from functional prototypes to robust, scalable solutions. This support directly addresses the 'DIY vs. Pro' dilemma, particularly for those innovating within the LoRa ecosystem.

Finding Your Balance

Ultimately, the "DIY vs. Pro" debate isn't about one being definitively better. DIY builds foundational skills and is perfect for experimentation. Professional PCBA provides the reliability, scale, and precision needed for complex, dependable products, especially in demanding fields like LoRa communications. Knowing when to transition is key. As your projects grow in complexity or require dependable deployment – particularly those leveraging the power of LoRa/LoRaWAN – exploring professional manufacturing options becomes a strategic advantage. Opportunities like Elecrow's make that exploration more accessible than ever.