What You Need to Know about Premium PCB Types & Applications

What You Need to Know about Premium PCB Types & Applications

Printed Circuit Boards (PCBs) are the foundation of contemporary electronics, offering the fundamental structure that drives everything from sophisticated medical equipment to cell phones. But not all PCBs are equal. Because more than 95% of client requests are satisfied by the Premium PCB Service. There is when premium PCBs are at the forefront. Premium PCB caters to specialized applications ( aerospace, automotive, and telecommunications ) with specialist features like multilayer boards (more than four layers), FPC with stiffener, Rigid-Flex, Immersion Silver (AG), etc. This guide will cover the main characteristics of premium PCBs, their several types, and the industries that depend on them to advance technology.

What is the Distinction of Premium PCB

One significant distinction between standard PCBs (1-6 layers) and premium PCBs (8-30 layers, HDI) is the materials and manufacturing techniques. Standard materials are used in regular PCBs like FR-4 (Tg130~150) and CEM-1/CEM-3, which are appropriate for general-purpose electronics. Premium PCBs, on the other hand, are constructed with significant, stable substrates, halogen-free alternatives, and high-performance FR4, providing higher reliability in demanding applications.

Additionally, drilling and plating are very different. For better performance and longevity, premium PCBs employ cutting-edge methods like laser micro-drilling and nanoscale graphene coatings, whereas standard PCBs rely on numerical control drilling and copper plating.

The fabrication procedures for both are quite different, too. Standard PCBs use simple techniques such as chemical etching, standard silkscreen printing, and direct printing for solder mask applications. However, more sophisticated methods, including vacuum etching, laser exposure, electrostatic spraying, and high-definition inkjet printing, are advantageous for premium PCBs. Premium PCBs are perfect for high-frequency, multi-layered, and high-density applications because of the increased precision these techniques produce, which enables them to accommodate complex structures, finer traces, and sophisticated patterns.

Regular PCB VS Premium PCB

|

Distinctions |

Regular PCB |

Premium PCB |

|

Layers |

1-6 |

8-30 layers plus HDI |

|

Material |

Standard materials |

halogen-free |

|

Fabrication |

Numerical control drilling |

Laser micro-needling plus numerical control drilling |

|

PTH

|

Copper plating; Conductive polymer coating;

|

Copper plating; Nanometer graphene coating; |

|

Electroplating |

Gantry style electroplate |

VCP continuous vertical plating + Gantry style electroplate |

|

Etching |

Chemical etching |

Chemical etching; Laser etching; Vacuum etching |

Types of Premium PCB & Applications

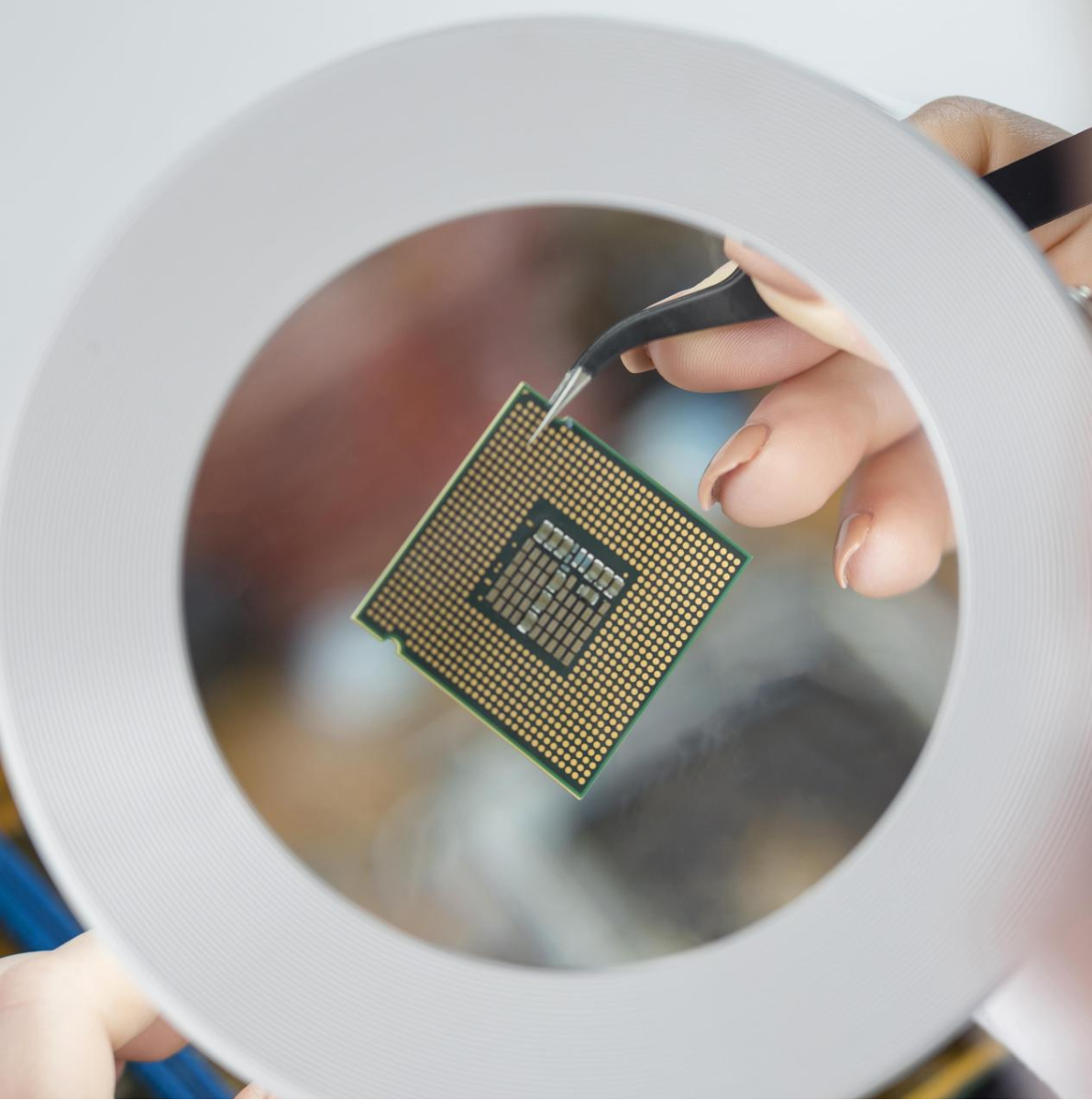

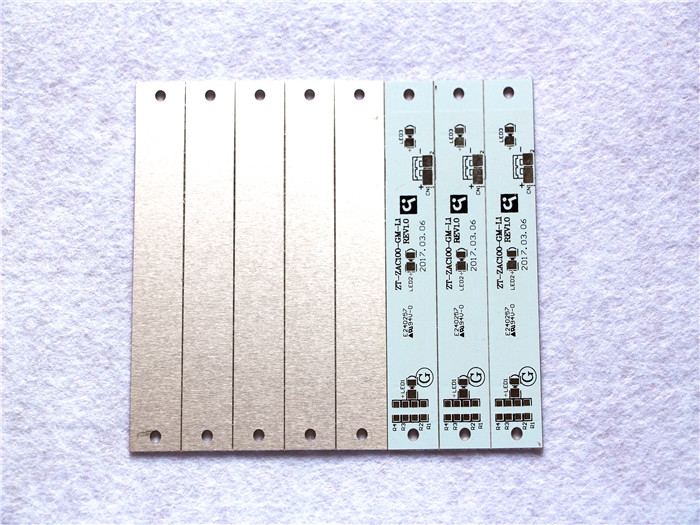

1. Aluminum PCB

Aluminum-printed circuit boards are a great option if your project calls for effective heat management. They are perfect for high-power applications like LED lighting, power conversion systems, and automotive electronics because of their superior heat-dissipating aluminum base layer. They offer ± 10% thickness tolerance.

Aluminum PCBs assist in keeping power modules and lighting systems from overheating when working on automobile projects. With PCB Premium, you can enhance various applications such as audio equipment (amplifiers and preamplifiers), power systems (switching regulators and converters), communication devices (high-frequency increasers), office automation, automotive electronics, and computer components like CPUs and power supplies.

2. Flex PCB

Flex PCBs are the answer for designs that must be flexible and small. Because of their flexible construction, these PCBs can bend, twist, or fold without breaking. Flex PCBs are particularly helpful in medical equipment, wearable technology, and communication devices with limited space.

Flex PCBs enable the development of portable, lightweight medical devices such as hearing aids and pacemakers. Their small size makes them compatible with smart home appliance accessories, allowing you to create stylish and inventive goods.

3. Copper Core PCB

Copper-core PCBs are the best option if your project requires high current capacity and superior heat conduction. Because of their thick copper layer, these PCBs are ideal for power-intensive applications such as industrial IoT devices, automotive power supplies, and new energy systems.

Copper-core PCBs offer the stability and thermal control required for energy storage systems or charging stations for electric vehicles. They also perform exceptionally well in industrial control systems, where great dependability in challenging conditions is crucial.

4. Rogers PCB

You have a clear advantage with Rogers PCBs for high-frequency applications. High-frequency laminates that make these PCBs provide superior electrical characteristics, reduced signal loss, and less thermal expansion.

Premium Rogers PCBs are essential for 5G systems, satellite communications, and high-speed networking because they guarantee signal integrity while developing communication equipment. They improve the efficiency of data transfer in IIoT applications, facilitating the smooth operation of your sensor networks.

Advantages of Premium PCB

- You get exceptional Durability with PCB Premium

- Enhanced Electrical Performance for Optimal Functionality

- It Provides superior Thermal Management Capabilities

- Greater Design Flexibility for Complex and Compact Devices

- You improved Environmental Sustainability with PCB Premium

Cost of Premium PCB Vs Regular PCB

Indeed, the initial cost of premium PCB services may be higher than that of standard options. Still, the long-term benefits you gain in durability, precision, quality control, efficiency, and innovation make them a cost-effective choice for high-quality manufacturing. By investing in premium PCBs, you can ensure the reliability and performance of your products, reduce maintenance and recall costs, and gain a competitive edge in the market. Thus, the cost-effectiveness of premium PCB services becomes apparent when you consider the broader perspective of product lifecycle and overall manufacturing efficiency.

Conclusion

Elecrow is your reliable partner for conventional and premium PCB solutions because of its dedication to product quality, prompt delivery, and customer satisfaction. Examine Elecrow Services, as it goes beyond your imagination to provide stable, long-lasting PCBs. Elecrow’s online automated quotation system streamlines ordering PCBs by providing instant, accurate pricing tailored to customer needs.

As customers select their specific parameters—such as board size, layer count, material, finish, and quantity—the price dynamically updates in real-time on the right side of the page. This transparent and user-friendly feature allows customers to experiment with different configurations and immediately see how each choice impacts cost, helping them make informed decisions quickly. The automated quotation tool not only speeds up the order process but also ensures clear, upfront pricing without any delays. Ready to be our partner? Visit for a premium PCB quote now!