What is CNC Machine Metal Cutting? A Comprehensive Guide

What is CNC Machine Metal Cutting? A Comprehensive Guide

Prologue

In today's rapidly advancing world, precision manufacturing plays a pivotal role in creating intricate metal components with unmatched accuracy and efficiency. At the heart of this transformative process lies CNC machine metal cutting. In this comprehensive guide, we will delve into the fundamentals of CNC machine metal cutting, exploring its principles, techniques, and applications. Whether you're a seasoned professional in the manufacturing industry or a curious enthusiast seeking to expand your knowledge, this guide will provide you with valuable insights and practical information to navigate the world of CNC machine metal cutting.

What is CNC Machine Metal Cutting?

Computer Numerical Control (CNC): CNC technology forms the foundation of CNC machine metal cutting. It involves the use of computerized systems to control the movements and operations of the cutting tool. The CNC machine interprets instructions from a computer program and translates them into precise movements, ensuring accuracy and repeatability.

Advantages of CNC Machine Metal Cutting

CNC metal machine cutting offers several advantages over conventional manual cutting methods:

- Precision and Accuracy: CNC machines can achieve high levels of precision and accuracy, ensuring consistent quality in the finished parts.

- Efficiency and Productivity: With automated operations and the ability to work continuously, CNC machines significantly improve productivity compared to manual cutting methods.

- Complex Geometries: CNC machines excel at cutting complex shapes and intricate geometries that would be challenging or impossible to achieve manually.

- Repetition and Consistency: CNC machines can produce multiple identical parts with consistent quality, reducing human error and ensuring uniformity.

- Versatility: CNC machines can perform a wide range of cutting operations, including milling, drilling, tapping, engraving, and more, making them suitable for various industries and applications.

Principles of CNC Machine Metal Cutting

CNC machine metal cutting is based on several fundamental principles that enable precise and efficient material removal from metal workpieces. Here are the key principles:

- Not All Metals Can Be Cut: Some machines can cut through tough metals such as steel, aluminum, and copper. However, not all CNCs are capable of this feat. The ability of a CNC machine to cut through metal depends on various factors, including its rigidity, spindle power, the cutting tool employed, and the metal's machinability.

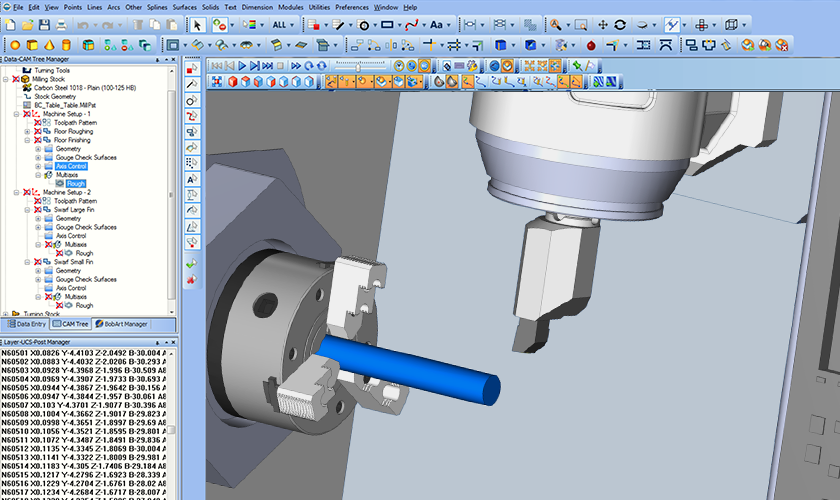

- CAD/CAM Software: CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software plays a crucial role in CNC machine metal cutting. CAD software is used to create a digital model or design of the desired part, while CAM software generates the tool paths and cutting parameters based on the CAD model. These programs provide the instructions necessary for the CNC machine to execute the cutting operations accurately.

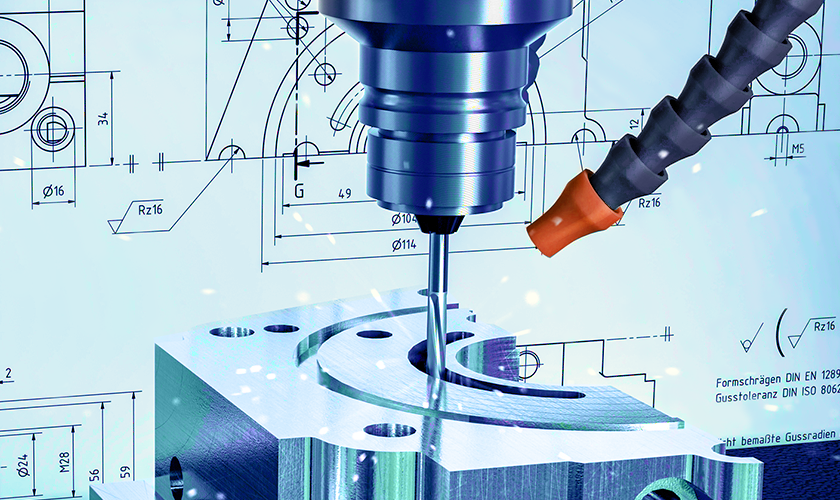

- CNC Machine Metal Cutting Tools:CNC machine metal cutting involves the use of various cutting tools, such as end mills, drills, taps, reamers, and more. These tools are mounted on a spindle, which rotates at high speeds to remove material from the workpiece. The selection of the appropriate cutting tool depends on factors such as the material being cut, the desired cutting operation, and the required surface finish.

- CNC Machine Metal CuttingTool Paths: Tool paths define the trajectory and movements of the cutting tool during the cutting operation. These paths are programmed into the CNC machine using CAD/CAM software. The CNC machine precisely follows the tool paths to remove material from the workpiece, resulting in the desired shape or design.

- CNC Machine Metal CuttingCutting Parameters: Cutting parameters include variables such as cutting speed, feed rate, depth of cut, and tool engagement. These parameters are determined based on factors such as the material being cut, the type of cutting operation, and the desired outcome. Optimizing cutting parameters is crucial for achieving efficient material removal and maintaining tool life.

- CNC Machine Metal CuttingWorkholding: Workholding refers to the methods and devices used to secure the workpiece firmly during the cutting process. Proper workholding is essential to ensure stability, accuracy, and safety. Common workholding methods include clamps, vises, fixtures, and chucks.

- Programming and Set-Up: CNC machine cutting requires programming the machine to perform specific operations. This programming is typically done using CAD/CAM software, where the tool paths, cutting parameters, and dimensions are defined. Once the program is created, it is loaded into the CNC machine, and the workpiece is securely clamped in place before the cutting operation begins.

There are still more principles to realize an efficient CNC machine metal cutting process, these basic rules guide the process and form the basis for creating precise, complex, and high-quality metal components.

Types of CNC Machine Cutting Operations

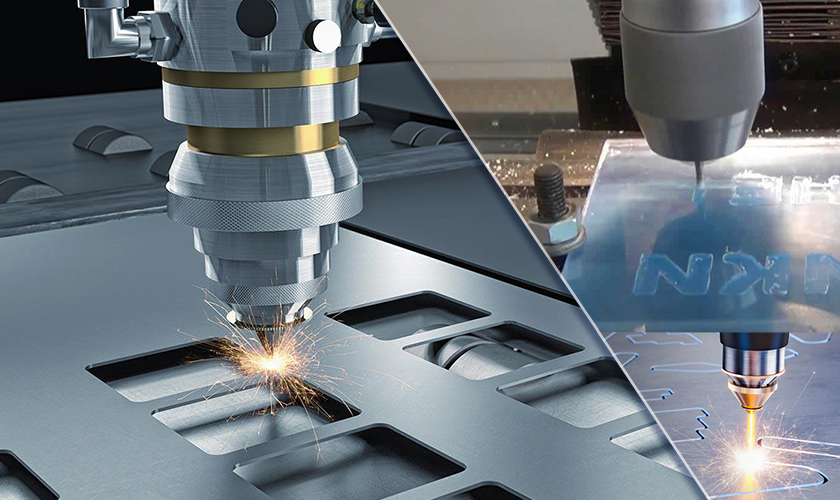

CNC machines are capable of performing various cutting operations, including:

- Milling: In CNC machine milling, the cutting tool rotates while moving along multiple axes, removing material to create flat or contoured surfaces.

- Drilling: CNC machines can accurately drill holes of different sizes and depths in workpieces.

- Turning: Turning operations involve rotating the workpiece while a stationary cutting tool shapes it, typically used for cylindrical or tapered parts.

- Tapping: CNC machines can perform tapping operations to create internal threads in workpieces.

- Boring: Boring operations enlarge existing holes or create precise cylindrical holes with tight tolerances.

- Reaming: Reaming is used to achieve high precision and smoothness in existing holes, improving their surface finish and size accuracy.

How to Make CNC Machine Metal Cutting Work Appropriately?

The process of cutting metal using a CNC machine is similar to other CNC metal machining operations. However, certain precautions must be taken to achieve a clean cut in metal workpieces.

Get a Rigid CNC Machine

If you want to cut metal on a CNC machine, the first step is to find a good one that is capable of doing so. Entry-level CNC routers are better for softer materials, while CNC mills are ideal for cutting metals. You can even build your own DIY CNC machine and use a strong router that can handle softer metals, such as aluminum. But it's crucial to make sure that the CNC machine or DIY build has a sturdy chassis to hold all the components and provide powerful cutting without any bending or flexing.

Secure Workpiece Clamping: Ensuring Stability

Before beginning the cutting process on a CNC machine, it's crucial to ensure that the workpiece is securely clamped to prevent any movement caused by cutting forces. There are several clamping techniques available, including T-clamps, Cam clamps, L-clamps, and double-sided tape. Double-sided tape is suitable for lightweight workpieces, while clamps are better for securely holding metal workpieces.

In addition, a vacuum bed can also be used for workpiece clamping. However, a powerful vacuum pump is necessary depending on the size and weight of the metal workpiece. It's important to note that most CNC machine brands don't include a vacuum bed table, so you may need to purchase it separately or create a DIY vacuum bed using your CNC machine.

Select an Appropriate CNC Machine Metal Tool

The tool used for cutting metal during machining impacts both the surface finish of the cut and the speed at which the cutting is done. CNC machining involves various parameters that directly or indirectly depend on the cutting tool's choice, including speed, feed, depth of cut, and chip load. Therefore, a durable cutting tool is needed to deliver strong cutting forces without snapping while machining metals.

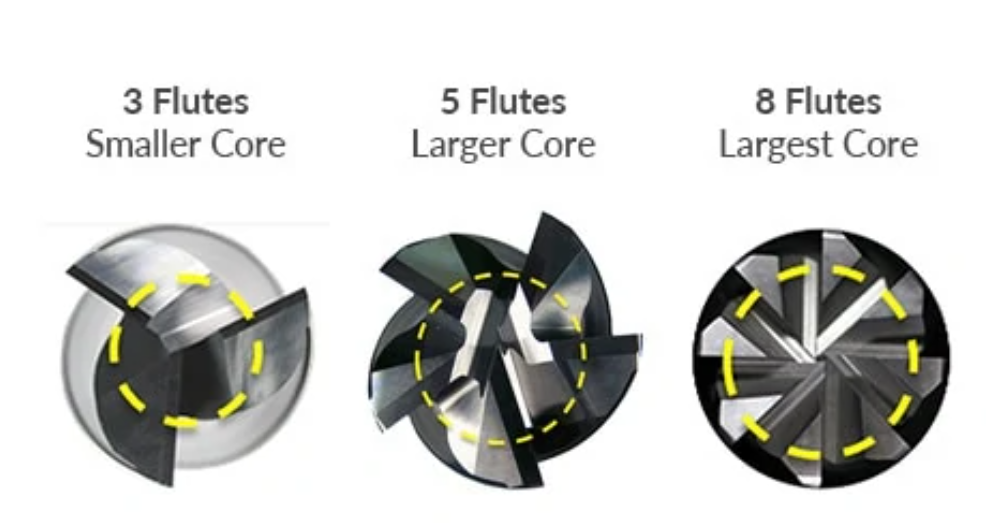

For CNC metal machining, it is generally recommended to use a carbide end mill as it provides the strength to deliver strong cutting force with minimal tool wear. The number of flutes on the end mill also has an impact on the cutting process. A cutting tool with fewer flutes, such as 1 or 2 flutes, provides easy clearance of chips, making it suitable for machining ductile metals like aluminum and copper. On the other hand, more flutes produce smoother cuts with less chip clearance.

Use Adaptive Cut

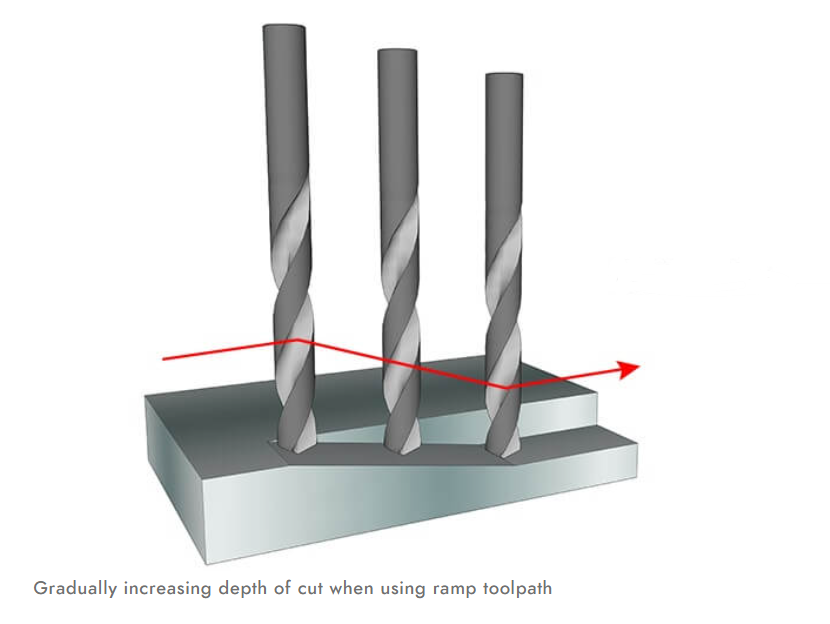

When using CNC machining, the high-speed rotating tool makes contact with the workpiece. This contact can create a high-impact load that may harm the cutting tool or workpiece. To avoid this, it is recommended to utilize an adaptive toolpath or ramp tool path. These methods gradually increase the depth of the cut, reducing the impact load. By doing so, the life of the tool is extended, while also producing a smoother cut with a better surface finish.

Use Cutting Fluid

When machining metal workpieces, there is a lot of friction which can create excessive heat and cause damage to both the workpiece and cutting tool. It's important to use a CNC cutting fluid to regulate the temperature at the cutting area and prevent overheating. The cutting fluid also acts as a lubricant to reduce frictional heat and improve the quality of the cuts made in metal workpieces. A typical coolant system consists of a fluid storage tank, a pump, and a delivery hose to transport the cutting fluid to the work area.

Final Words

CNC machine metal cutting has revolutionized the manufacturing industry by offering precise, efficient, and highly versatile cutting capabilities. Its ability to create intricate parts with exceptional accuracy has made CNC machine metal cutting an indispensable manufacturing way across various industries. At Elecrow, we are not only a leading PCBA provider but also possess over a decade of expertise in CNC milling services. We are dedicated to delivering professional CNC milling services tailored to the specific requirements of makers and manufacturers.

Moreover, if you're a maker with innovative ideas and aspire to transform them into tangible products for profit, Elecrow's Partner Seller Program is the perfect opportunity for you. By joining our Partner Seller Program, you can bring your ideas to life on a large scale, leveraging our professional guidance and assistance. We'll help you turn your concepts into solid projects, facilitate online sales, and enable you to earn substantial profits through our platform. Don't miss out on this exciting opportunity to realize your creative potential and achieve financial success with Elecrow!