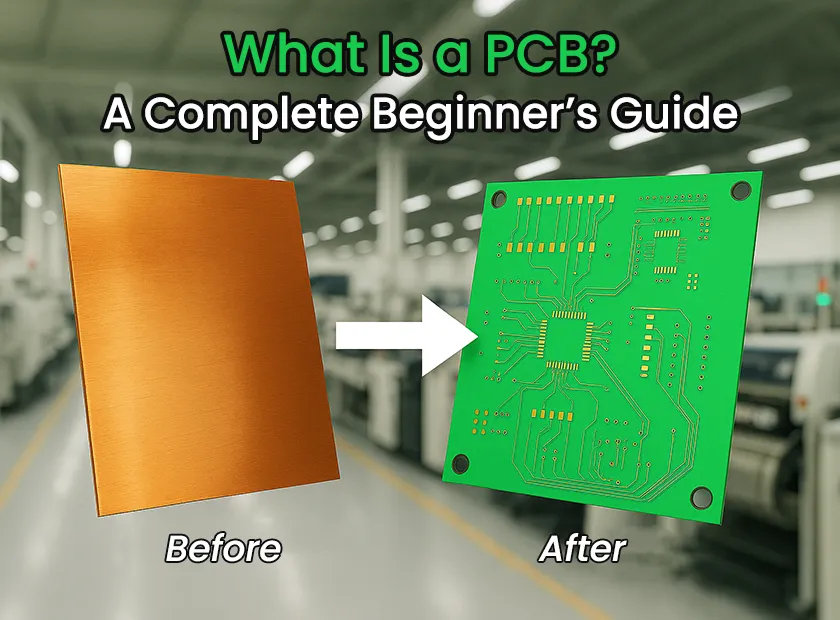

What Is a PCB? A Complete Beginner’s Guide

What Is a PCB? A Complete Beginner’s Guide

In today’s tech-driven world, nearly every device you use—from your smartphone and TV to your washing machine and electric toothbrush—relies on a silent, essential component: the Printed Circuit Board, or PCB. For beginners, sourcing professionals, or anyone curious about electronics, understanding PCBs is a great first step toward understanding how modern technology functions.

This guide will walk you through the fundamentals of PCBs, their types, internal structure, and how they power the devices we use every day.

What is a Printed Circuit Board?

A Printed Circuit Board (PCB) is a thin board made from insulating material, typically fiberglass, that contains conductive copper traces to connect electronic components. These traces act like tiny highways that carry electrical signals between components like resistors, capacitors, microchips, and connectors.

Rather than wiring each part by hand, PCBs offer a much neater and more efficient way to build electronic circuits. They provide a stable platform for mounting components and ensure they work together as a complete system.

In short, a PCB is the physical and electrical foundation of almost every electronic device.

The Evolution of PCBs

Before PCBs, electronic circuits were assembled using point-to-point wiring—a labor-intensive process prone to errors and shorts. The invention of the PCB brought standardization, automation, and durability to electronics manufacturing.

As electronics have become more compact and sophisticated, so too have PCBs. Today’s boards can contain multiple layers of circuitry, support advanced materials for high-speed data, and integrate both rigid and flexible sections to fit into compact or oddly shaped devices.

Types of PCBs

PCBs are designed in different forms to meet specific performance and space requirements. Here are some of the most common types:

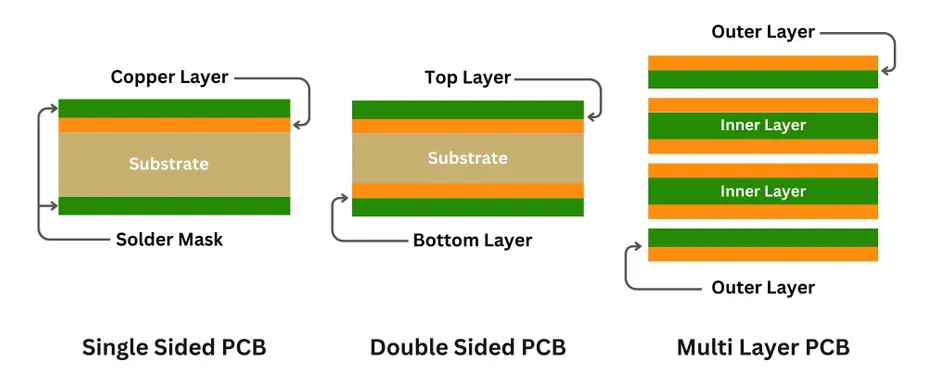

Single-sided PCBs

These boards have one layer of copper on one side. They’re simple, low-cost, and typically used in basic electronics like toys, calculators, or small appliances.

Double-sided PCBs

With copper traces on both sides, these boards allow more complex circuits and denser component placement. They are widely used in consumer electronics and industrial devices.

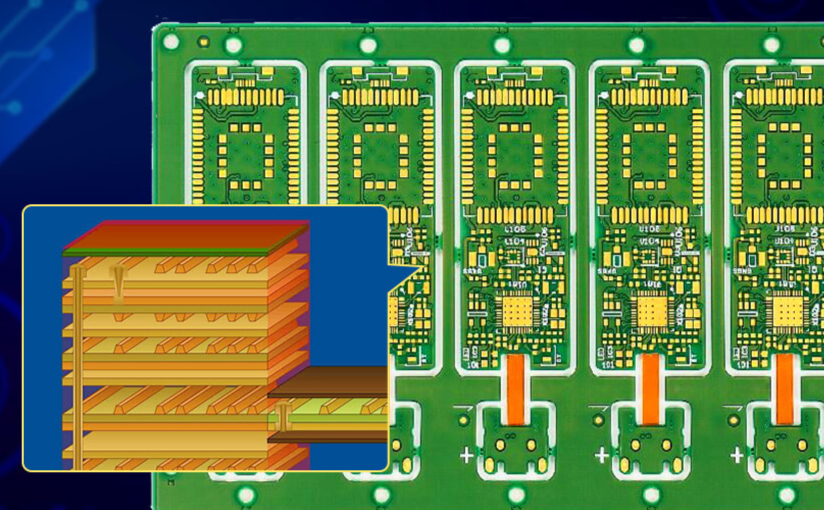

Multilayer PCBs

These PCBs have three or more layers of copper circuitry, stacked with insulating layers in between. They’re essential in computers, smartphones, and medical instruments where performance and compact size are crucial.

Rigid PCBs

Made from solid fiberglass (usually FR4), these boards retain their shape and are the most common type in everyday electronics.

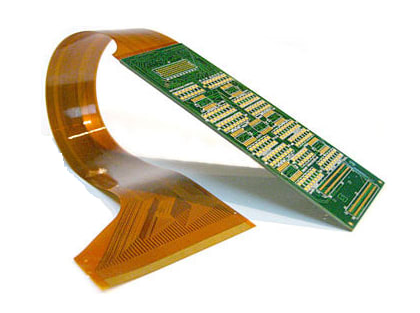

Flexible PCBs

Built on bendable materials like polyimide, flex PCBs can curve or twist, making them ideal for wearable tech, medical devices, and cameras.

Rigid-Flex PCBs

A hybrid of rigid and flexible boards, these are used in products like foldable phones, aerospace controls, and medical imaging systems that require both stability and flexibility.

Printed Flex PCBs

These ultra-thin and lightweight boards are used in high-density, space-constrained devices like smartwatches and hearing aids.

Metal-Core PCBs

Also known as MCPCBs or IMS (Insulated Metal Substrate) PCBs, these use a metal base—often aluminum—for superior heat dissipation. They’re perfect for LED lighting, power supplies, and automotive electronics.

HDI (High-Density Interconnect) PCBs

These compact boards support microvias and fine traces, enabling high-speed connections in tight spaces. HDI PCBs are vital for smartphones, tablets, and high-performance wearables.

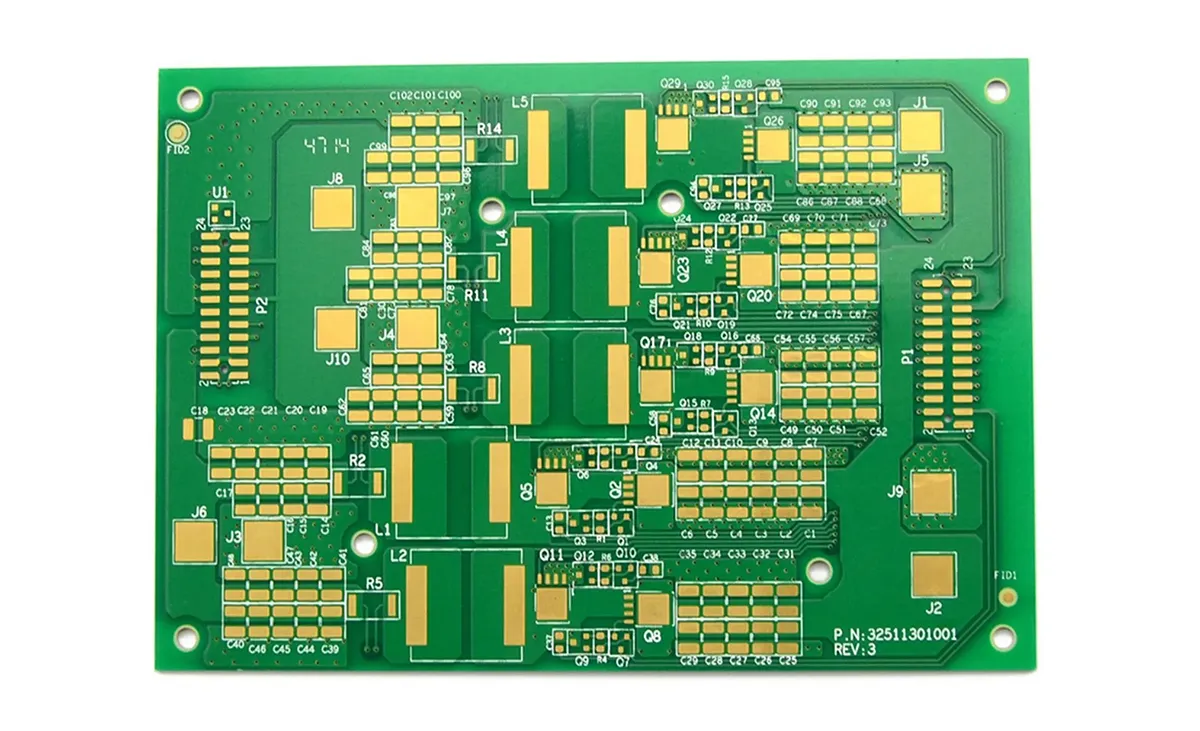

What’s Inside a PCB?

Though PCBs can look very different depending on their use, they typically share a common internal structure:

● Substrate (Base Layer): This non-conductive material provides structural strength. Most commonly, it's fiberglass (FR4).

● Copper Layer: Thin copper sheets form the circuit paths. Single-sided boards have copper on one side, while double-sided and multilayer boards have copper on multiple layers.

● Solder Mask: This green (or sometimes red, blue, or black) coating protects the copper traces and prevents solder bridges between components.

● Silkscreen: Printed text or symbols on the board help identify components and guide assembly or troubleshooting.

Also included are traces (copper pathways), pads (metal points where components are soldered), and vias (holes that connect layers).

How PCBs Power Our World

PCBs are more than just a structure—they’re the nervous system of electronics. Inside a device, the copper traces on a PCB act like roadways, directing electrical signals to different parts of a circuit. This flow of electricity enables various components to perform tasks, whether that’s displaying a number, detecting a button press, or sending a wireless signal.

Because of their versatility and reliability, PCBs are used in virtually every industry:

● Consumer Electronics: Smartphones, laptops, tablets, TVs, smartwatches—all powered by compact, multilayer PCBs that handle everything from user input to video playback.

● Automotive: PCBs control everything from engine management systems and electric steering to entertainment and parking sensors. As electric vehicles grow, so does the demand for thermal-resistant, high-current PCBs.

● Healthcare: Medical monitors, imaging systems (like MRI machines), and wearable health devices depend on precision-engineered PCBs for accuracy and reliability.

● Industrial and Manufacturing Equipment: Machines in factories use PCBs in control panels, robotics, and automation systems to improve productivity and safety.

● Aerospace and Defense: Here, PCBs must withstand extreme temperatures and vibrations while ensuring mission-critical functionality in radar systems, navigation equipment, and communication devices.

● IoT and Smart Devices: From smart doorbells to home assistants, these devices pack powerful PCBs into small enclosures, enabling wireless connectivity, sensors, and cloud access.

The role of a PCB in all these applications is to provide a stable and efficient pathway for power and information—ensuring devices operate correctly, consistently, and compactly.

PCB vs. PCBA: What’s the Difference?

It’s easy to confuse these terms, but they represent different stages of the electronic assembly process:

● A PCB is the bare board—just the copper traces and insulating layers with no components.

● A PCBA (Printed Circuit Board Assembly) is the completed board with components mounted and soldered on, ready to be used in a device.

For sourcing professionals, this distinction is important. When purchasing, always confirm whether you're ordering the raw board (PCB) or the fully assembled board (PCBA).

Printed Circuit Boards are the heart of modern electronics. Whether you're flipping a light switch, sending a text, or navigating with GPS, there’s a PCB working behind the scenes.

By understanding what a PCB is, the different types available, and how they make devices function, you gain a deeper appreciation of the tech around you—and a better foundation for sourcing decisions, product development, or hands-on exploration in electronics.

No matter where you’re starting from, a solid grasp of PCBs is a powerful first step into the world of technology.