Currency

What is 3D Printing? How does 3D Printing Work?

September 21, 2022

With the development of modern science and technology, 3D printing is becoming a more household word to all of us since the world’s first recorded 3D printer invented by the Japanese inventor Hideo Kodama in the 1980s. Over time, the 3D printing world has quickly spread to many parts of the workforce. The groundbreaking invention of the 3D printers has always kept the world in utter shock.

What is 3D Printing?

3D printing uses computer-aided design to create three-dimensional objects through a layering method. Sometimes referred to as additive manufacturing, 3D printing involves layering materials, like plastics, composites or bio-materials to create objects that range in shape, size, rigidity and color. To put it simply, 3D printing is a way to manufacture complex objects easily with an economical price. 3D printing is cheaper, faster, and more customizable than buying a product from a store. This technology provides:

faster production times

better quality

tangible design

product testing

cost-effectiveness

Different types of 3D printing:

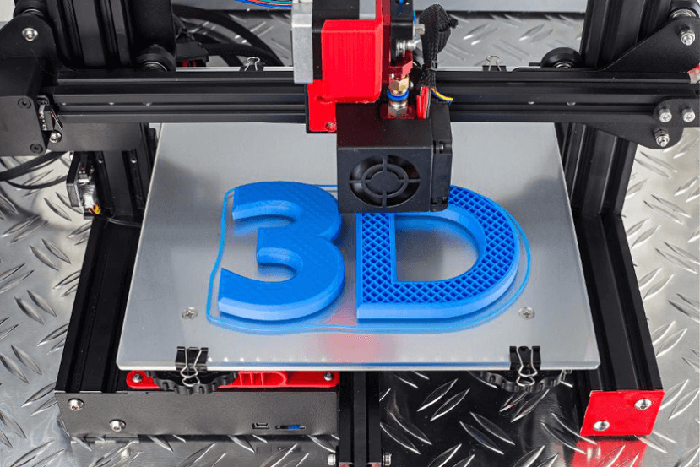

3D printing machines with different technology set them apart from other kinds. They vary from each other in printer cost, print quality, print speed and printer capability. There are 8 commonly used 3D printing technologies: Polyjet, Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM), Digital Light Process (DLP), Multi Jet Fusion (MJF). Among these, FDM 3D printing is the easiest 3D printing type for beginners. Not only is the process easy to understand but the raw materials are inexpensive and the equipment can also be found at very affordable prices.

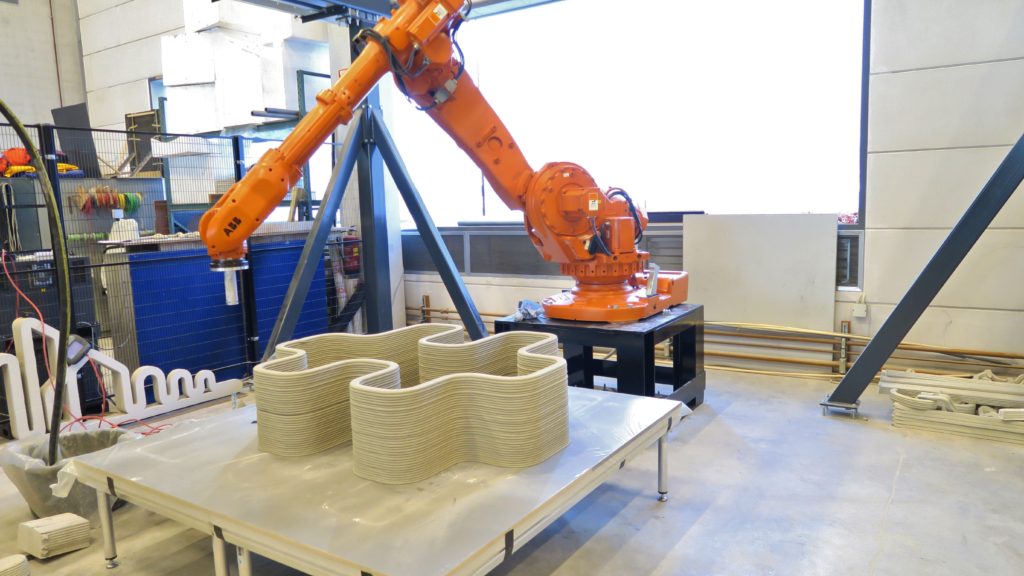

Applications of 3D Printing:

3D printing is widely applied in areas like Automotive, Aerospace, Architecture, Food, Health care and even in Fashion industry. In a few years from now, it is very much possible that 3D printing can be used to print entire, usable human organs!

In the TV series Westworld, scientists have already been able to print simulated human tissues with 3D Printing technology. Cooperated with AI technology, creating a realistic human being became a reality. Although this only happens in science fiction now, it may come true one day in the future. No one knows.

Back to now, prototyping is one of the most widespread applications of 3D printing. It was during the days of the inception of 3D printing that designers and engineers came to realize that if they chose to have their prototypes printed and not machined, they could exponentially save money and time.

How Does 3D Printing Work? - STL Files for 3D Printing

Every object printed on a 3D printer starts with a 3D model. These are usually made in a CAD program designed for working on real-world 3D models, like TinkerCAD, Fusion360, or Sketchup. A digital 3D model is sliced into hundreds of thin layers by dedicated software to export in G-code (G-code is used mainly in computer-aided manufacturing to control automated machine tools) format. This 3D printing format is a language that the 3D printer reads to know precisely when and where to deposit material. Each layer corresponds to the exact 2D shape of one section or slice of the object. The layers are consecutively 3D printed one at a time until you obtain the fully printed object.

When it comes to 3D Printing, you can not bypass a related subject, STL (stereolithography) file. An STL file is a simple, portable format used by computer aided design (CAD) systems to define the solid geometry for 3D printable parts. Each file is made up of a series of linked triangles that describe the surface geometry of a 3D model or object. The more complex the design, the more triangles used, and the higher the resolution. The resolution of the STL file impacts the quality of the 3D printed parts. If the file resolution is too high the triangle may overlap. If it is too low the model will have gaps, making it unprintable. Since the STL format is the most common file format in 3D printing, many 3D printers require an STL file to print from.

How to Realize:

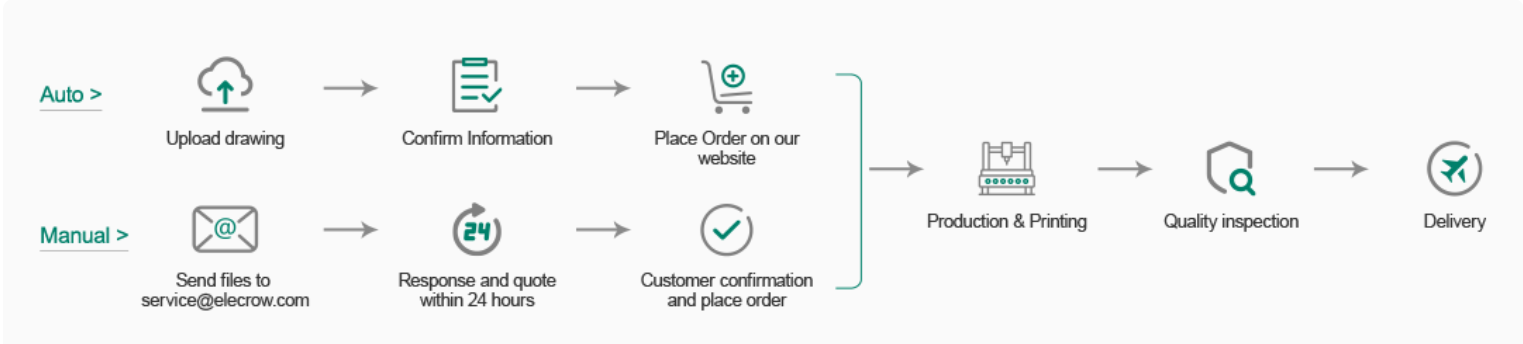

If you want to 3D print an object but you don’t have a 3D printer or you’re too busy to look for the nearest shop near you, don’t worry. Elecrow will provide you with the latest and cost-effective Online 3D Printing Service. Elecrow commits to carefully and efficiently process every product complying fully with customers’ requirements. Elecrow regards quality as its first priority. ISO9001 certificate is the basic requirement. Elecrow ensures the proper operation of its quality control system and guarantees the quality of all the products/parts ordered.

Good news is that Elecrow is launching an awesome Autumn 3D Printing & Acrylic Promotion on the official website from September 19th. The price of Photosensitive resin (domestic 9400) for 3D printing starts from $10. All you need is to Upload your STL File for 3D printing on Elecrow 3D Printing Service page, and you will receive our instant quote. Now it is time to give it a try and let your imagination fly!