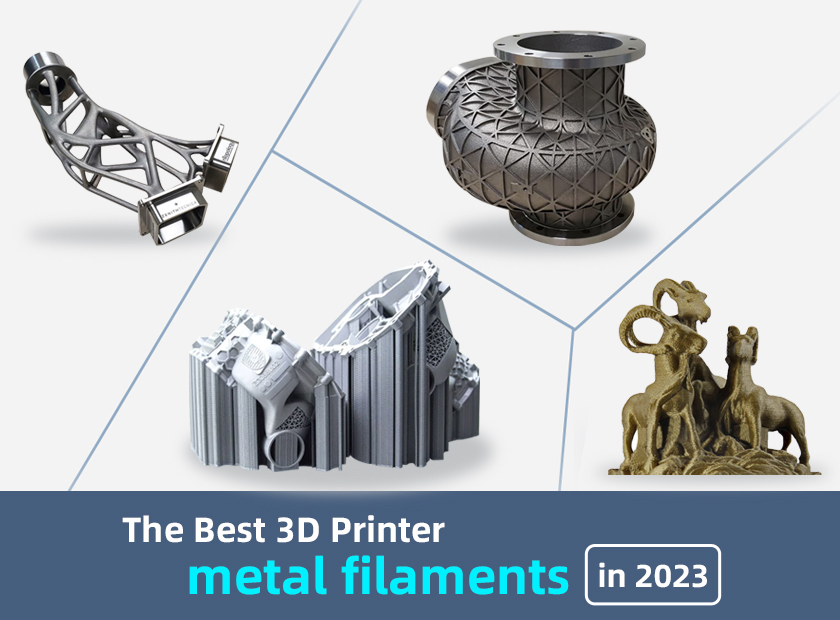

The Best 3D Printer metal filaments in 2023

The Best 3D Printer metal filaments in 2023

The 3D Printer Metal filament is stronger, more durable when compared to regular plastic filament like PLA, knowing the best 3D Printer metal filament is essential for makers to complete electronics projects that require materials of high performance.

What Is 3D Printer Metal Filament?

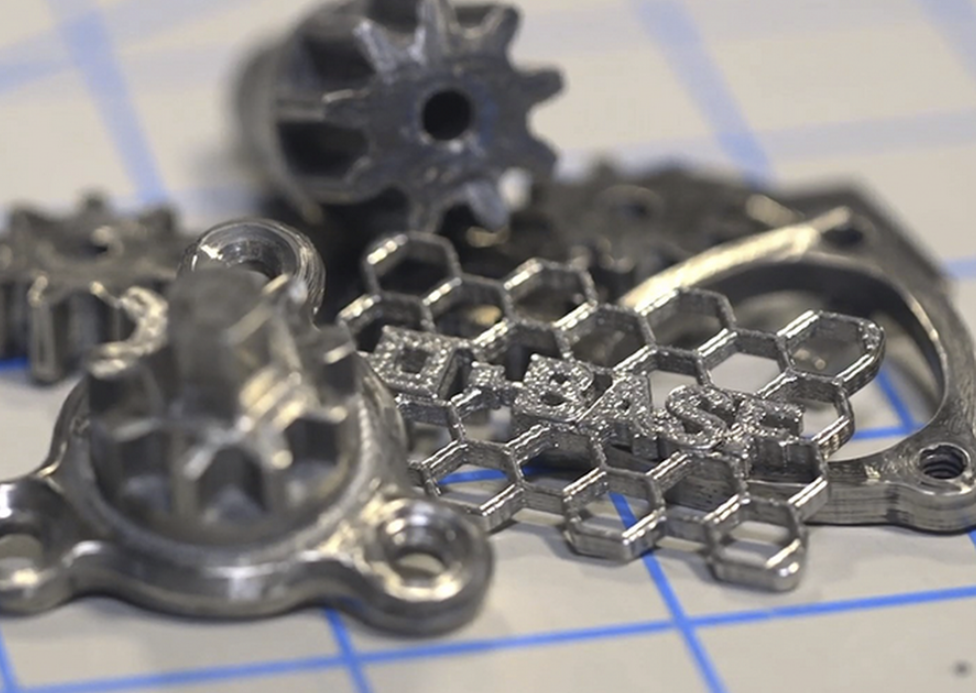

3D Printer Metal filament is a sort of material users can use for 3D printing, it’s a plastic base that contains metal particles evenly infused throughout. This composite filament can be used to print metal parts made of strong, chemically resistant, and solid metal components.

It's easy to understand how metal-infused plastic filament works if you've ever used carbon fiber or glass filament, but there's one significant difference. For metal parts infused with metal filament, the plastic is removed in a one- or two-step process after printing, leaving only the metal (or most metal) behind.

To produce metal parts, metal filaments must contain a high percentage of metal powder (around 80%) and must undergo post-processing steps to remove plastic components and condense metal.

High Cost of 3D Printer metal filament

Metal filaments offer a cost-effective alternative to industrial metal printers, but they are usually more expensive than standard filaments. Depending on the amount and type of fill, metal filaments can cost at least twice as much as PLA or ABS filaments. It's important to pay attention to the amount you're getting, as metal filaments are often sold in smaller quantities of 500 grams or less, compared to the standard 1-kg spools of regular filaments. To sample different materials, you can look for low-cost "samples" in 100-gram coils to avoid committing to a whole roll.

Metal filaments have a higher density than PLA or ABS filaments, which means that a spool of the metal filament may be shorter than expected for the same weight. It's a good idea to check the length specifications at the point of purchase to avoid disappointment.

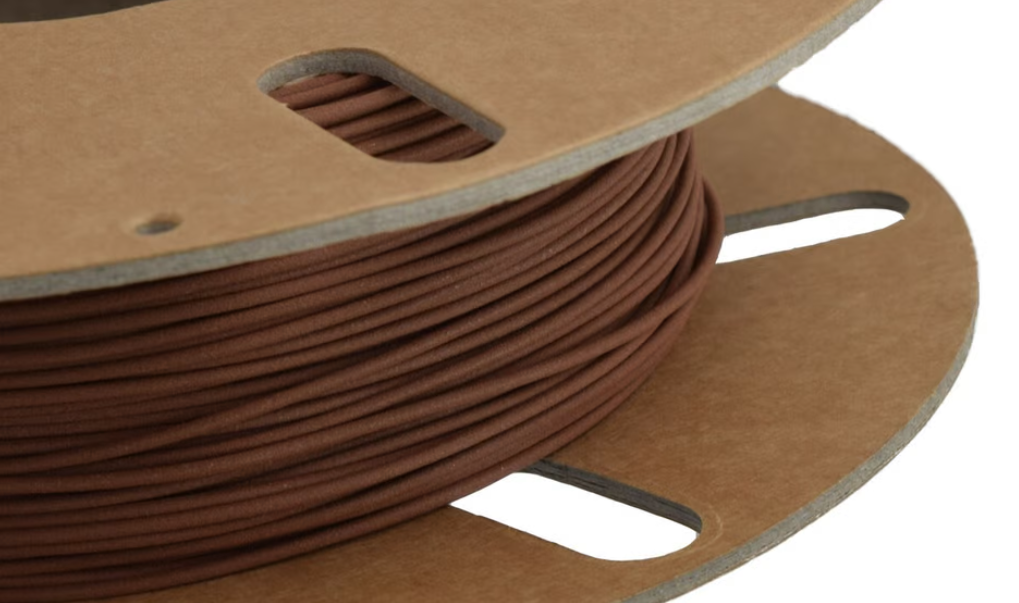

ProtoPasta (10-15%)

Headquartered in the USA, Protoplant has been in the 3D Printer filament business since the early days, with its ProtoPasta filament brand offering consumers five 3D Printer metal filaments covering copper, brass and bronze filled heat-treated PLA (HTPLA) as well as steel and iron filled composite PLA.

By heat treating HTPLA filaments at 110°C for 10 minutes, printed objects made from this material become significantly stronger and harder. Water and vinegar-based washes can be used in the post-processing of these iron-filled metal filament printed articles to achieve different ageing effects.

The percentage of metal by volume in all five materials is close to 10 to 15%, as they consist mainly of PLA with densities ranging from 1.85 to 2.3 g/cm3.

While ProtoPasta is often recommended for high quality printing, there are some drawbacks to its metal blends. Firstly, the spools are made of cardboard rather than plastic, which may not roll as smoothly. Secondly, the filament is brittle and requires careful handling and stricter printing conditions than normal filaments.

Specifications

Price: $70-$100 for 1 kg

Spool sizes: 100 g, 500 g, 2 kg

Printing Temperature: 185-230 °C

Bed temperature: Up to 60 °C

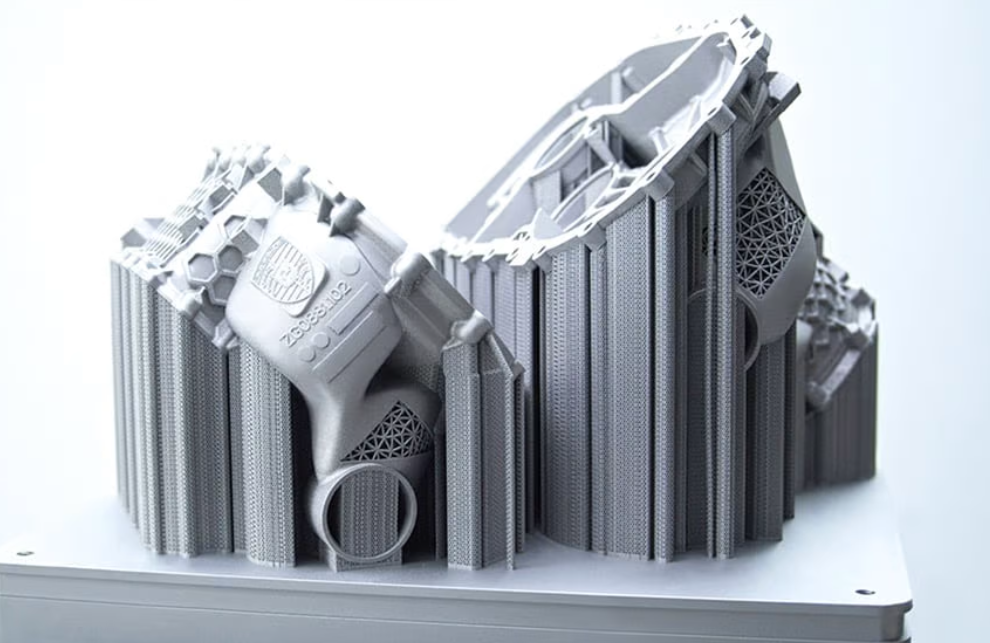

BASF Ultrafuse 316L (~100%)

BASF's Ultrafuse 316L filament and the following product are unique entries on this list because they require additional post-print processing to produce a nearly 100% metal end product. Ultrafuse 316L filament is a metal-polymer composite that contains a high percentage of 316L stainless steel, making it ideal for industrial parts that require high strength.

A debinding and sintering process removes the polymer from the part and fuses the metal together, resulting in a denser and more compact final product. However, this process requires additional effort and cost beyond printing on a standard FDM 3D Printer at home.

The Ultrafuse 316L filament is only available in stainless steel and is available in both 1.75mm and 2.85mm widths. Due to the high initial metal content, bed adhesion issues may occur and the sintering process may cause shrinkage in the finished part. MatterHackers recommends using a glass print bed with Dimafix adhesive and scaling up parts by 120% to overcome these issues.

Specifications

Price: ~$155 for 1 kg

Spool size: 3 kg

Printing Temperature: 230-250 °C

Bed temperature: 100-120 °C

Gizmo Dorks

Gizmo Dorks is a reliable filament brand due to its variety of products, quality, and popularity, and two metal-filled PLA filaments appear in its product lines: copper and bronze. However, it is claimed that the metal content of these filaments is relatively low at 5% compared to previously introduced metal filaments, and Gizmo Dorks doesn't make it clear whether this value refers to volume or weight.

Nevertheless, they produce good-looking models and can help users achieve great results; due to the lower volume of metal they contain, this type of metal filament is easier to 3D print, it's relatively easy to work with, and has a competitive price, making it a reliable and cost-effective choice for users.

Specifications

Price: ~$25 for 1 kg

Spool size: 1 kg

Printing Temperature: 190-225 °C

Bed temperature: Up to 70 °C

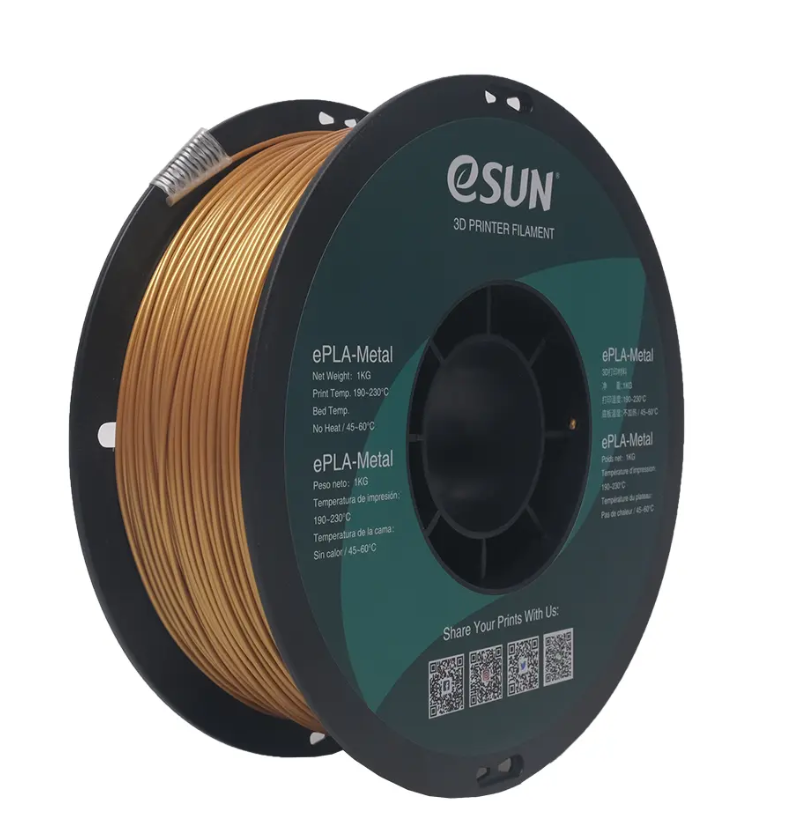

eSun (10-15%)

For those interested in metal 3D printing, eSun, the brand familiar to 3D Printer enthusiasts, has introduced a lineup of low-cost, entry-level metal 3D Printer filaments. Available in bronze and copper, the lower metal content makes the 3D pinter filament less prone to clogging and easier to print, while still leaving enough material for polishing. This type of filament is mainly made from PLA, so it's better for users to set print parameters close to those of the base material.

The recommended printing temperature for 3D Printer filament is between 180 and 210°C, with a heated bed around 50°C. A 0.5mm or larger hardened steel nozzle is also recommended.

The recommended printing temperature for 3D Printer filament is between 180 and 210°C, with a heated bed around 50°C. A 0.5mm or larger hardened steel nozzle is also recommended, as brass nozzles are susceptible to wear from the abrasive metal filament. Despite the low metal content of the filament, at 10% by volume it's still enough to erode brass.

WildRoseBuilds on YouTube has demonstrated an effortless method of achieving a stunning polished finish on eSun eMetal prints. The process involves using a highly abrasive sponge to smooth out pits and layer imperfections, followed by lower grit sandpaper with water to even out the surface. Finally, polishing paste and a cloth are used to allow the print to shine on its own, resulting in a beautiful finish.

Specifications

Price: ~$50 for 1 kg

Spool sizes: 500 g, 1 kg

Printing temperature: 180-210 °C

Bed temperature: Up to 50 °C

Ooznest Metal (25-30%)

Ooznest, a company based in the UK, was founded with the aim of democratizing the RepRap project and making home engineering projects accessible to makers. They specialize in providing a range of parts, materials, and upgrades for 3D printing and CNC milling, enabling users to easily produce a wide variety of small-scale projects.

Ooznest offers two colors of filament, "Penny Copper" and "Vikings Bronze," which contain between 25-30% metal content and have densities of 3.39 and 3.41 g/cm3, respectively. To achieve desired finishes, Ooznest recommends a post-processing phase, particularly when aiming for a polished or oxidized look. This allows for a broad range of aesthetics, from shiny and futuristic to rustic and Steampunk.

It's important to note that UV light can significantly impact the shelf life of the filament, so Ooznest recommends keeping the spools stored in a location away from direct sunlight.

Specifications

Price: ~$72 for 1 kg

Spool sizes: 500 g

Printing temperature: 210 °C

Bed temperature: Up to 60 °C

AlSi10Mg

Printing aluminum requires quite strict conditions, traditional 3D printing sometimes cannot meet the standard of aluminum printing.Laser powder bed fusion (LPBF) is the most commonly used technology for aluminum 3D printing, but not every printer using this technology can handle aluminum. Due to the unique properties of the aluminum-based alloy used, LPBF printing parameters must be carefully optimized and calibrated to ensure that porosity, microstructure and final material properties are properly controlled. As a result, it's common to see certain partnerships and collaborations between material suppliers and printer manufacturers as they work together to achieve the best possible results for their customers.

Uniformity Labs has launched UniFuse AlSi10Mg, an aluminum powder for laser powder bed fusion 3D printing that improves with scale. Equispheres released two materials: NExP-1, a non-explosive aluminum alloy feedstock that reduces handling hazards, and Performance AlSi10Mg powder that reduces print time by over 60% when used in laser powder bed fusion 3D printing.

Ti6A14V titanium alloy

Titanium and its alloys, such as Ti6Al4V, play a crucial role in 3D printing due to their unique properties. Titanium is found in nature as an oxide, and pure titanium is obtained through the Kroll Method, which involves obtaining titanium tetrachloride (TiCl4) by chlorination and then reducing it with magnesium or ground sodium. Due to its high reactivity, pure titanium is difficult to obtain, so it's often used in combination with other elements to form an alloy.

Titanium is known for its high mechanical strength, low density, and excellent corrosion resistance, making it a popular choice in several industries, including aerospace and medicine. However, its high cost is a significant downside. Nevertheless, the unique properties of titanium alloys make them ideal for additive manufacturing, offering vast potential for the production of parts and components.

Final Words

If you're a maker looking for high-quality 3D printing services that can produce intricate metal parts, Elecrow is an excellent option. Their range of printing technologies, including FDM, SLA, and SLS, enable the creation of highly detailed parts in a variety of materials, including metals such as A316L stainless steel, AlSi10mg aluminum alloy, and Ti6A14V titanium alloy.

By combining Elecrow's expertise in electronics manufacturing with 3D printing, customers can benefit from a unique range of solutions to bring their ideas to life.

Whether you're a hobbyist or a professional looking to prototype or produce small metal parts, Elecrow's 3D printing services, PCB manufacturing, PCB assembly and component sourcing services offer a comprehensive solution that can help take your project to the next level.

If you are not satisfied with DIY electronics projects and want to mass produce your fantastic ideas, turn them into commercial products and sell them online, you can rely on Elecrow's Partner Seller Program. As an Elecrow Partner Seller, you can get professional support from Elecrow and easily earn benefits here!