Seven Factors That Determine PCB Prices

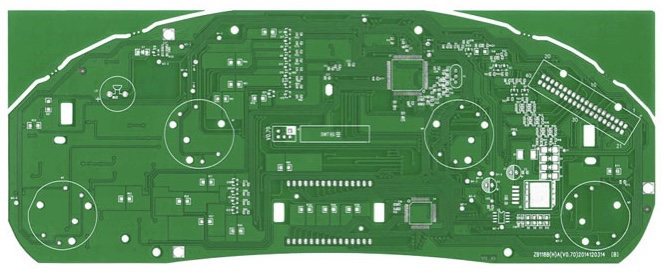

Substrate used for PCB

Taking ordinary double-sided panels as an example, the sheets generally include FR-4, FR-1, CEM-1, CEM-3, etc. The board thickness varies from 0.2mm to 3.0mm, and the copper thickness varies from 0.5 ounces to 6 ounces. All of these have caused a huge price difference in the sheet. The difference of the sheet metal suppliers makes the sheet of uniform specifications also have a price difference of tens of yuan per square meter. Even the same board supplier has several specifications. In addition, inks, character inks, etc., so the difference in materials causes the price variety.

Different regions cause price diversity

There are certain differences in prices in different places, so different regions also cause price diversity.

- PCB board cost (different board, cost is different).

- Drilling costs (the number of holes and the size of the aperture affect the drilling costs).

- Process cost (different process requirements of the board lead to different process difficulties, and even prices will vary).

- Manual water and electricity plus management costs.

PCB surface treatments vary greatly in production costs

Different surface treatments will cause different costs. Such as gold-plated PCB and tin-sprayed PCB, making shape gongs and die punches. The use of silk screen lines and dry film lines will result in different costs, leading to price diversity.

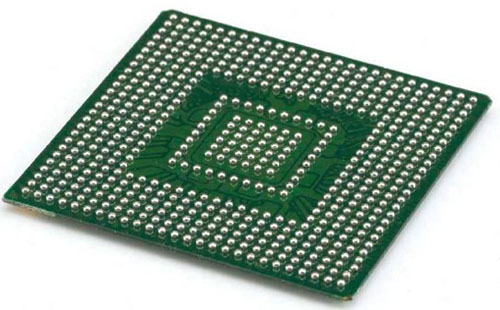

Different PCB difficulty causes different prices

The difficulty of PCB itself will also cause different costs. If you want to look at the circuit on the PCB, if the wire density is less than 4/4mm, the price will be calculated separately, whether there is a BGA bit, etc. There are 1000 holes on the two kinds of circuit boards, and the hole diameter of one board is greater than 0.6mm and the hole diameter of the other board is less than 0.6mm, which will result in different drilling costs. For example, the two circuit boards are the same, but the line width and line spacing are different, one is greater than 0.2mm, and the other is less than 0.2mm, which will also cause different production costs. Because of the higher scrap rate of difficult boards, the cost will inevitably increase, which will result in price diversity.

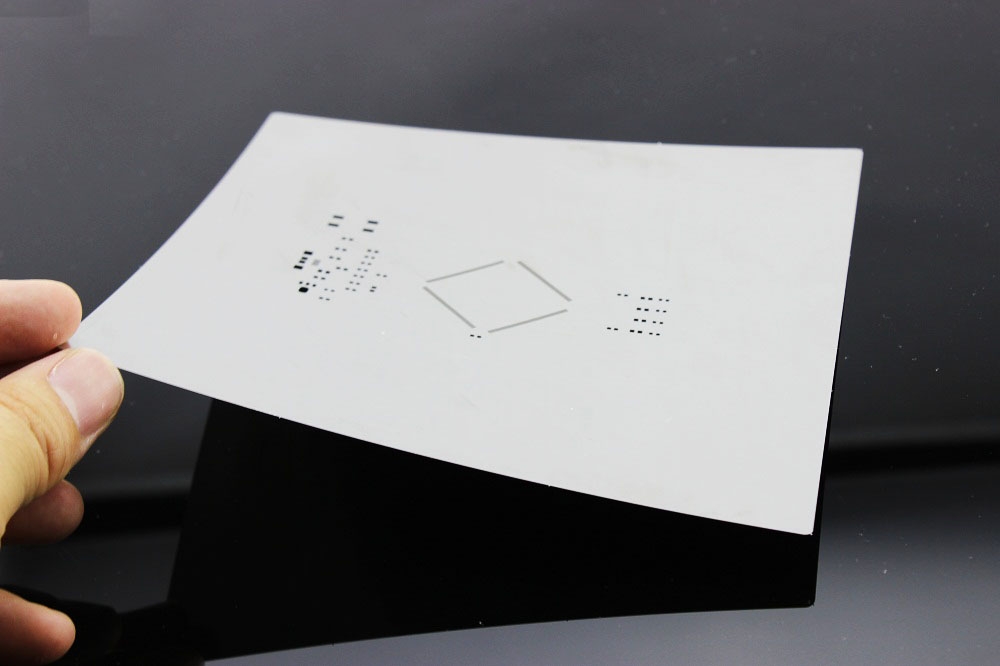

Stencil

A PCB stencil is a small piece of material with holes that affect the layout of parts on a board. PCB Stencil can be divided into seven types: laser stencil, electropolishing stencil, electroforming stencil, step stencil, bonding stencil, nickel plating stencil and etching stencil. There are three methods for manufacturing SMT stencil: chemical etching, laser cutting and electroforming. The price of stencil depends on its thickness, size and type. Elecrow project manager will check the gerber files and your required specifications for the quoting. The default specification would be 1.6mm thickness/hasl/green. You can also visit Elecrow PCB manufacturing page for reference.

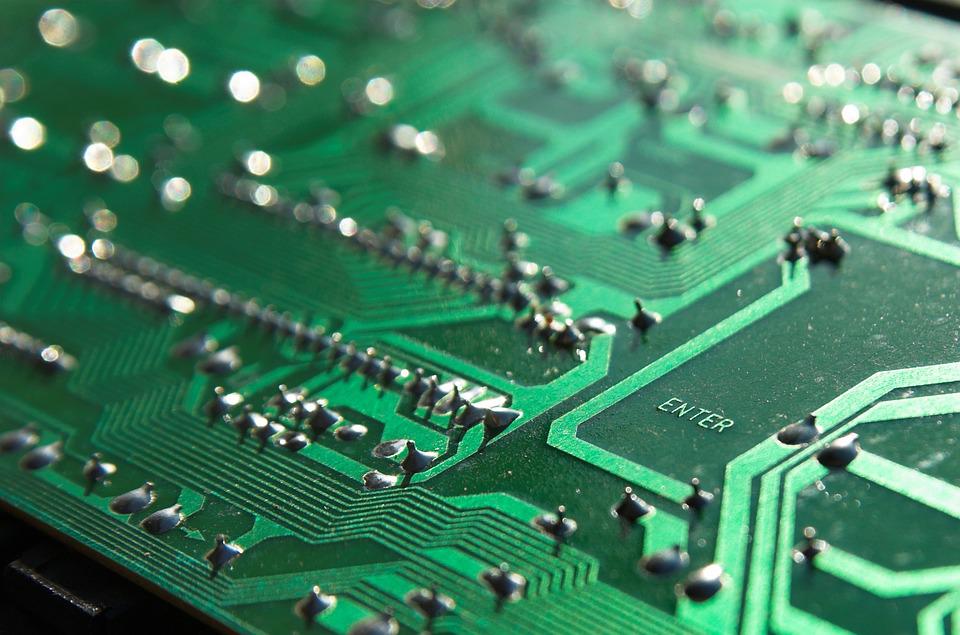

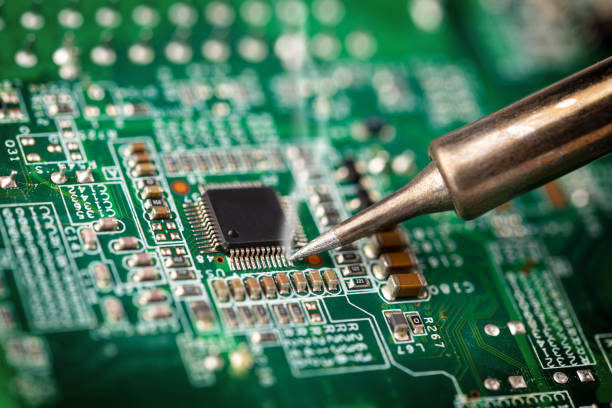

Soldering price

Soldering means joining metal components together with melted metal called solder, which has a lower melting point than the other metals. It is a process crucial in the electronics industry and is the primary method of joining electrical components together. Soldering is a fundamental skill in the context of electronics. Because the optimum functioning of electronic devices and appliances relies on the soundness of a PCB, proper soldering is vital. This means expert PCB soldering techniques for maximum efficiency.

PCB manufacturers are different

Even for the same product, because different manufacturers have different process equipment and technical levels, different costs will result. Nowadays, many manufacturers like to produce gold-plated panels because of the simple process and low cost. However, some manufacturers produce gold-plated panels, and the scrap will increase, resulting in higher costs. Therefore, they prefer to produce tin-sprayed panels, so their quotation for tin-sprayed panels is instead of gold-plated panels low.

Then how to reduce PCB assembly costs?

Spend enough time to present a complete list of classified materials. A valid BOM should include all basic elements such as reference mark, part number, description, quality, SMT method, manufacturer name, footprint, packaging and BOM level. The most important thing is to add component replacement elements in the BOM. Because technology is evolving faster, and it is necessary to immediately replace old elements with new ones to match competitive market trends.

Consciously choose professional experts and reliable PCB manufacturers/PCB assemblers. Most PCB assemblers claim to provide cost-effective PCB assembly services. But many customers are not satisfied because they have not received what they claim. In order to avoid these important problems, choosing a reliable and creditable manufacturer will save you a lot of trouble in the future.

Elecrow is a professional expert who can meet the requirements of PCB assembly, PCB manufacturing, PCB layout, PCB prototyping and PCB rework. Elecrow has a mature system and various testing methods to ensure manufacturing your PCBA with high quality. Our PCB expert team is ready to provide you with support to reduce PCB costs without affecting the quality.

We cherish every relationship with customers, and making every customer satisfied with our services is our goal. Welcome to contact us!