Awarding Gold Inspectors: Visual Inspection Competition for PCB Assembly

Awarding Gold Inspectors: Visual Inspection Competition for PCB Assembly

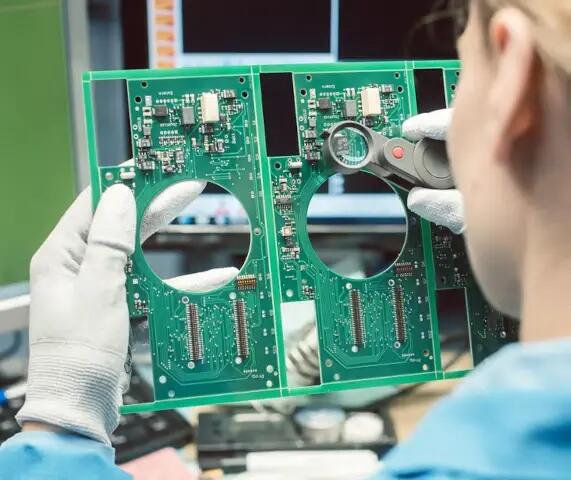

Shenzhen, China –The PCB manufacturer and assembler, Elecrow, conducts a Visual Inspection Competition for PCB Assembly. The competition engaged the entire QC team at Elecrow and comprised both theoretical and practical components. The Visual Inspection segment, a critical facet of PCB quality control, was evaluated by the judge—an Automated Optical Inspection (AOI) equipment—which determined the competition's winners. From a pool of skilled QC team members, two emerged victorious, showcasing their mastery of the intricate art of PCB assembly. Congratulations to the two winners!

The Importance of PCBA Visual Inspection

PCB Visual Inspection is a pivotal quality control process in the production of Printed Circuit Boards (PCBs). There are several intricate steps in the process of PCB assembly, including the precise placement and soldering of numerous electronic components. Visual inspection is indispensable in verifying the accuracy and integrity of these processes, ensuring compliance with required specifications and industry standards.

The Goal of PCBA Visual Inspection

The primary goal of visual inspection is to identify defects and inconsistencies in assembled PCBs, including soldering issues, misaligned components, missing elements, and solder bridges. Therefore, visual inspection guarantees that components are placed accurately and aligned according to design requirements, confirming correct orientation.

By identifying defects early in the manufacturing process, visual inspection contributes to the production of high-quality and reliable PCBs. So, visual inspection allows for timely rework or repair, minimizing the risk of costly scrap or rework in later production stages.

Visual inspection, acting as a complementary process to automated methods, also aids operators in verifying results obtained from AOI or X-ray systems. It ensures adherence to specific quality standards, regulatory requirements, and industry regulations, ultimately boosting customer satisfaction and meeting their needs.

The results of visual inspection provide valuable insights into manufacturing issues, offering a foundation for process improvement and continuous quality enhancement. Delivering defect-free, high-quality PCBs not only meets customer expectations but also fosters trust and confidence in Elecrow's products.

Visual inspection allows operators to examine challenging-to-access areas, such as solder joints under components or between tight spaces. This comprehensive approach ensures a thorough evaluation, contributing to the overall reliability and functionality of the finished PCBs. Elecrow's commitment to excellence demonstrated through the Visual Inspection Competition, reinforces its dedication to delivering top-tier PCB solutions while upholding the highest industry standards.

Established in 2014, Elecrow has emerged as a prominent provider of open-source hardware and electronic components. With an extensive array of offerings, the company caters to a global clientele, delivering exceptional products and services, including PCB manufacturing, PCB assembly, warehousing, logistics, and co-selling services. Elecrow's unwavering commitment to innovation, superior quality, and competitive pricing has established Elecrow as a reputable and dependable collaborator for makers, technology enthusiasts, and industry experts worldwide.

For more information about Elecrow, please visit www.elecrow.com.

CONTACT: Victor, marketing@elecrow.com

SOURCE Elecrow