What is the difference between PCB and PCBA?

What Is the difference between PCB and PCBA?

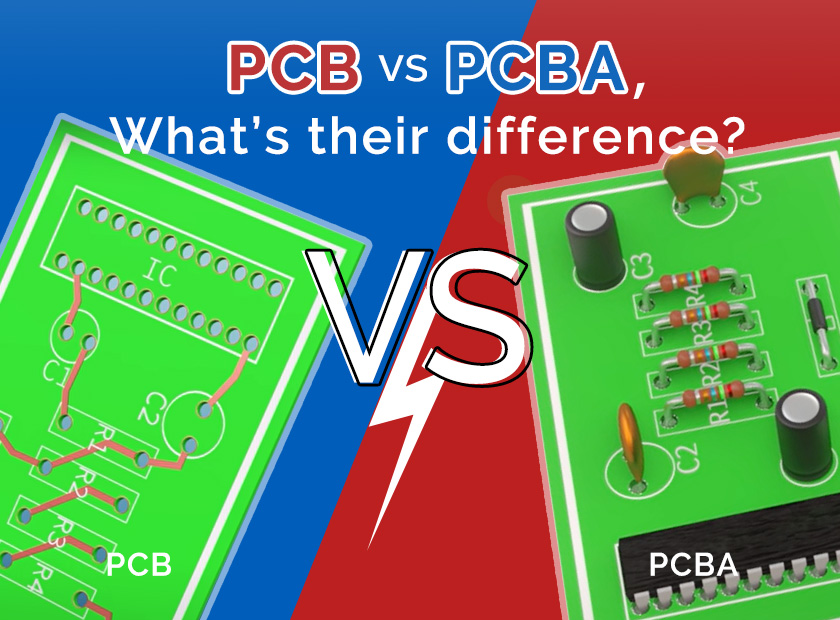

If you're a maker or tech geek in the electronic market seeking PCB or PCBA products, you've probably observed the tiny difference between them, one with “A” while the other without, so what’s their difference?

PCB(Printed Circuit Board) and PCBA(Printed Circuit Board Assembly) are both important terms in the electronics industry. Many people use them interchangeably, but they are two different things.

The main difference between PCB and PCBA is that PCB refers to bare boards, whereas PCBA refers to a completed board with all the electronic components mounted all the way around to make it work as intended. Unlike PCBs, which do not contain the required components, PCBAs are complete and functional boards. PCBs and PCBAs are two different stages of the same process; PCBAs are built on top of existing PCBs.

Keep reading to learn more about the difference between PCB and PCBA!

What Is the Definition of PCB?

In modern electronics, PCBs are the basic building blocks. Mechanically supporting and electrically connecting components, PCBs are made of laminate materials, such as fiberglass or composite epoxy. Conductive pathways are printed and inscribed on the board to join different electronic parts as the predetermined PCB design suggests.

Types of PCBs

There are several types of PCBs as follows:

Single-layer PCBs: Single-layer boards, sometimes called single-sided boards, have components on one side of the board and a conductor pattern on the opposite side. They have just one layer of conductive material, typically copper. A single-layer board is comprised of a substrate layer, a conductive metal layer, and then a protective solder mask and silk screen. You'll find single-layer boards in many simpler electronic devices.

Double-layer PCBs: Double-layer PCBs, aka double-layer or double-sided board, which has more layers than a single-layer board but fewer than a multi-layer. Double-sided PCBs, like the single-sided variation, have one substrate layer. The difference is that they have a layer of conductive metal on both sides of the substrate.

Multi-Layer PCBs: Multi-layer PCBs are made of three or more double-sided boards stacked on top of each other. Theoretically, they can contain as many boards as you can need, but the largest one ever made was 129 layers thick. Multi-layer boards typically appear in more complex devices that require a high number of connections. Paths known as vias allow the different layers to conduct to each other. These paths fall into three groups: Through-Hole, Blind via, and Buried via.

There are other PCB types as well including flexible PCBs, rigid PCB, and flex-rigid PCBs.

Applications of PCBs

You can see PCBs being used in a variety of applications, not limited to commercial or industrial electronics, but also robotics, heavy machinery, vehicle parts, and medical area. See more here:

- Illumination & Lighting systems

- Consumer &Industrial Electronics Industry

- Aerospace Industry(Satellite systems included)

- Telecommunication Industry(Radios,TV, Cell phones,Telecom Towers included)

- Maritime Industry

- Medical & Healthcare Industry(Pacemakers,Medical imaging systems included)

- Automotive Industry

- Computers

- Printers

- Calculators

- Engine management systems

- Data storage equipment

What Is the Definition of PCBA?

Types of PCBAs

Different from PCB as a bare board, a PCBA is a finished PCB assembly that needs all of the electronic components mounted to make it work as predesigned. PCBA may also be the process of assembling the board with vital electronic parts.

Two primary methods are used by manufacturers these days to do PCB assembly:

Surface Mount Technology (SMT): This technology is the most widely utilized for PCBA. As the name implies, SMT attaches components directly to the surface of the PCB using solder paste and does not require any holes in the board. This method allows components to be mounted to both sides of the board, allowing for more components on a given board and smaller PCBs compared to PCB assembly using THT only.

Through-Hole Technology (THT): This technique runs component leads through pre-drilled holes in the PCB. This method is not utilized as frequently as SMT but is known for its reliability and strong connections that in some cases can endure more vibration and stress than boards assembled with SMT.

Usually, the PCBA process works as below, the steps and sequencing may vary slightly depending on whether SMT or THT technologies – or a combination of both:

Apply Solder Paste-Place the Components-Soldering-Inspect the Assembly-Testing.

Applications of PCBAs

PCB and PCBA connect very well with each other, PCBA works the same in many industries as PCB does.

PCB VS PCBA

In a conclusion, a PCB is a bare Board with no electronic components. Once all the necessary electronic components are soldered onto the PCB, it is called PCBA. IPCB and PCBA are closely related to each other in electronics.

It’s simpler to Manufacture a blank board than produce a finished PCBA because of the different components and processes involved in PCB assembly. Producing a PCBA costs more than producing a blank PCB. However, creating a completed board needs both steps. PCB manufacturing is the first step in the process, and PCBA manufacturing builds upon that first step. Without PCB (Printed Circuit Board) there cannot be PCBA (Printed Circuit Board Assembly)

How PCBs and PCBAs are packaged are also different from each other. PCBs are typically packaged using vacuum packaging, while PCBAs require the use of compartmental or anti-static packaging.

Elecrow PCB & PCBA Services

Elecrow provides cost-effective full featured custom PCB prototype and PCB assembly services for customers around the world, to learn more about how our PCB assembly services can keep up with your demand, contact us online or see our website: