Currency

How to Reduce Cost with Panelizing Service

August 17, 2017

Panelizing is common used in the PCB board’s production for it can get more value in a low cost. For some customers, the size of single boards can’t properly used on their project so they need a bigger size. That’s the main reason for customer choose panelizing service, here is an introduction of panelizing service of Elecrow.

We have two ways of panelizing, one is V-cut and the other is snap off holes.

For V-cut, the minimum size of board is 8*8cm. V-cut is a straight and uninterrupted line, the mini spacing between 2 V-cut line is 2mm, and different thickness has different request. For 1.6mm thickness boards, V-cut line must has 1mm spacing with the edge of boards; for 1.0mm thickness should be 0.7mm. Customer can add the V-cut line in the GKO layer or the silkscreen layer, and should remark that there is V-cut line in silkscreen layer.

The snap off holes can use in irregular shape of PCB while the V-cut can’t, if you want to panelize irregular shape of PCB, please write your request in order comment so that we will send the panelized file for you to confirm before produced.

We have 3 styles of panelizing in V-cut and snap off holes:

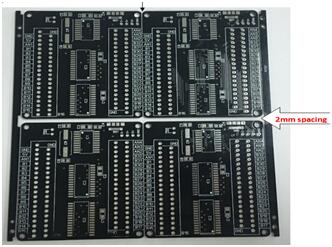

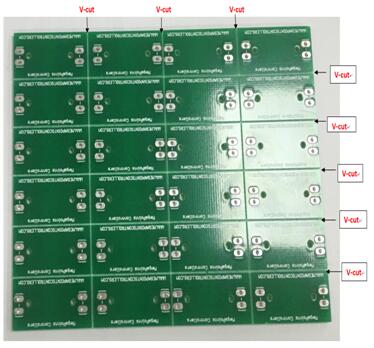

First is panelize with no spacing, here is the picture

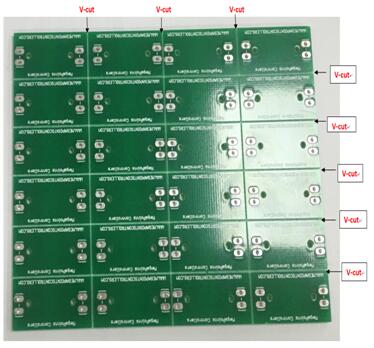

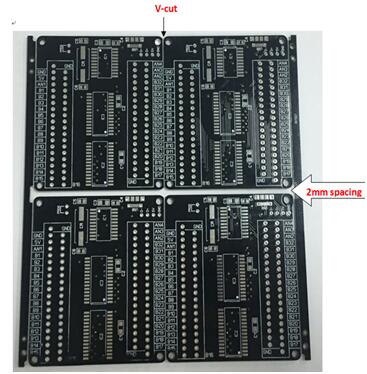

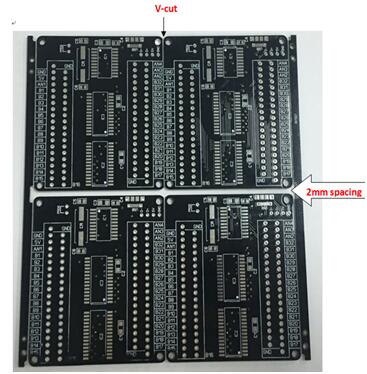

Second is panelize with spacing, here is the picture

Second is panelize with spacing, here is the picture

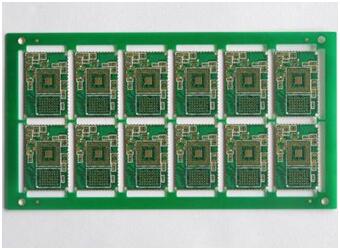

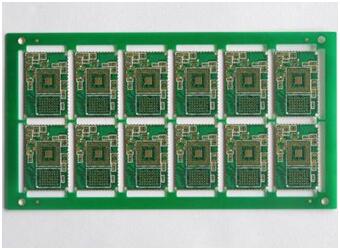

Third is panelize with margin, if you want to panelize the boards with margin, please write your request in your order comment.

Third is panelize with margin, if you want to panelize the boards with margin, please write your request in your order comment.

We need to charge panelize fee which decided on the designs quantity. Same designs (all data must the same) panelize with V-cut, the panelize fee is decided by the quantity of panelized boards.

2~5 copies, cost $8

6~10 copies, cost $12

11~30 copies, cost $16

30copies more, cost $32

If there has more designs in your file, the panelize fee is decided by the different designs quantity. We don’t care about the quantity of boards, one more designs need to charge $12.

If you have different circuit design, panelizing would be a great way to reduce the cost.

Click to to apply this method right away >>> Elecrow PCB Prototyping

We need to charge panelize fee which decided on the designs quantity. Same designs (all data must the same) panelize with V-cut, the panelize fee is decided by the quantity of panelized boards.

2~5 copies, cost $8

6~10 copies, cost $12

11~30 copies, cost $16

30copies more, cost $32

If there has more designs in your file, the panelize fee is decided by the different designs quantity. We don’t care about the quantity of boards, one more designs need to charge $12.

If you have different circuit design, panelizing would be a great way to reduce the cost.

Click to to apply this method right away >>> Elecrow PCB Prototyping

Second is panelize with spacing, here is the picture

Second is panelize with spacing, here is the picture

Third is panelize with margin, if you want to panelize the boards with margin, please write your request in your order comment.

Third is panelize with margin, if you want to panelize the boards with margin, please write your request in your order comment.

We need to charge panelize fee which decided on the designs quantity. Same designs (all data must the same) panelize with V-cut, the panelize fee is decided by the quantity of panelized boards.

2~5 copies, cost $8

6~10 copies, cost $12

11~30 copies, cost $16

30copies more, cost $32

If there has more designs in your file, the panelize fee is decided by the different designs quantity. We don’t care about the quantity of boards, one more designs need to charge $12.

If you have different circuit design, panelizing would be a great way to reduce the cost.

Click to to apply this method right away >>> Elecrow PCB Prototyping

We need to charge panelize fee which decided on the designs quantity. Same designs (all data must the same) panelize with V-cut, the panelize fee is decided by the quantity of panelized boards.

2~5 copies, cost $8

6~10 copies, cost $12

11~30 copies, cost $16

30copies more, cost $32

If there has more designs in your file, the panelize fee is decided by the different designs quantity. We don’t care about the quantity of boards, one more designs need to charge $12.

If you have different circuit design, panelizing would be a great way to reduce the cost.

Click to to apply this method right away >>> Elecrow PCB Prototyping