Elecrow PCBA Service

With this service, you do not need to suffer from soldering these very tiny pins of IC especially SMT, BGA, etc. Besides, Elecrow provides some other service includes Fusion PCB, Components Sourcing, System testing, etc. You can get all the service that you need in your designing& manufacture, now all in Elecrow.

1. How Elecrow PCBA Works, and What files needed for Quotaton& Production

For every customer, you will have a specific project manager at Elecrow. Send the following files to service@elecrow.com for quotation:

- 1. PCB Gerber files;

- 2. BOM of your project;

- 3. Quantity and PCB spec;

- 4. Parts mapping for soldering with parts machine, or a simple mapping for hand soldering;

- 5. Your specific requirements, or some reminds to avoid mistakes;

- 6. Your shipping address and shipping method you want , HK DHL/Shenzhen DHL/FedEx/register air mail supported;

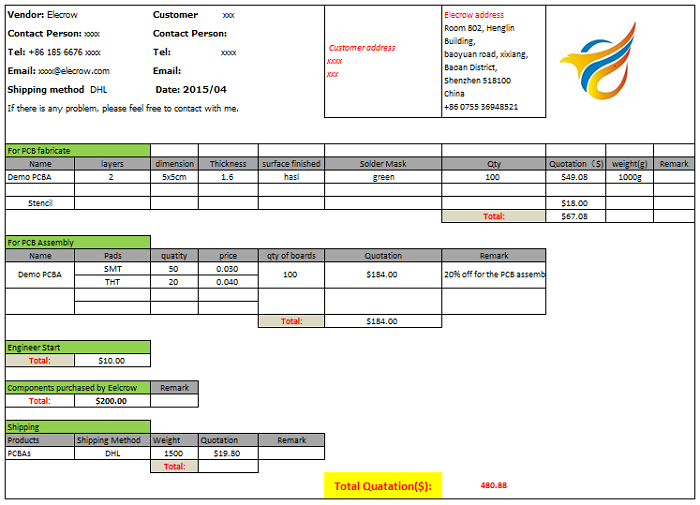

After receiving your files, we will prepare you a detail quotation. The quotation will consist of the following item:

- PCB fabrication is for the PCB cost, Elecrow will make the quotation based on the PCB layer, dimension, pads finish, and your other requirements. Besides, a stencil is needed for SMD soldering;

- PCB Assembly is the for the solder cost. Elecrow will charge the soldering fee based on the quantity of pads, with discounts depend on the quantity and soldering difficulty;

- Engineer Start fee is for the engineer start, will be $10 for each project.

- Components fee is the fee of components that Elecrow provided. Elecrow can provide & source most of the main components& modules. Customers can check the detailed components quotation in the “parts” sheet of quotation file.

- Shipping: Elecrow provide most of the popular shipping service such as HK DHL/Direct DHL/ FedEx/Registered Air Mail. Please leave us your shipping address for the shipping quotation. Note that the 300$ free shipping policy do not apply to the PCBA service.

2. PCB & Stencil

Besides the Gerber files, Elecrow project manager will check the files and you required specifications for the quoting. The default specification would be 1.6mm thickness/hasl/green. You can also read the Q&A for Elecrow PCB service for reference. Please check this as your received the quotation and notify us if you need to alter the specification.

A stencil is used for the SMD components soldering. With the stencil, the SMD components would be easy to solder; if you do not need a stencil, we will solder all the components by hand.

3. Components

Elecrow can provide& source most of the popular used components or modules. Users can send your BOM with part numbers and quantity to us, we will check every components and quote for them. Besides, Elecrow provide the Elecrow Part Library , which are stocked at Elecrow warehouse, customer can use these components, with lower price and ensured quality.

Some notes about the components:

- 1. For the components in user’s BOM, Elecrow may use substitute brands for the resistors /capacitors/connectors and some other common used components. These components are tested and popular used in Shenzhen market, they may reduce your cost largely. We will remarks this in the quotation: original brand or substitute brands.If you have special requirements on this, please let us know.

- 2. For the components we can’t source or if you can get them with lower price, you can also send us the components partly or all. If you sending them from other country than China, please note the Shipping Tips.

- 3. Depend on the sourcing difficulty, Elecrow may charge you some sourcing fee. This fee is for the sourcing work and only charges once. It will be free in your next prototyping round or mass production round.

4. PCBA Assembly

Elecrow provides high quality assembly service. We can solder the most common used package such as 0201/0402/0603/QFP/QFN/BGA/THT. We do not have any minimum quantity limitations. You can make the very first 1 pcs prototyping PCBA, or make thousands for your mass production.

As the customer requirements, we can solder the PCBA with hand or with reflow oven. For quantity>50 pcs, we will use the pick-and-place machine to place the components. Besides, lead free soldering available for the ROHS compatible. Part mapping file maybe needed for the components placement with pick-and-place machine.

As the cost, the soldering cost will depend on the quantity of Pads, 0.03$ for SMD Pads(with stencil) and 0.04$ for THT pads, with discounts based on the quantity; for prototyping round less than 20 pcs, 5$ will be added for each design.

5. Engineer & Test

Elecrow provide basic testing for the PCBA. Elecrow will make visual inspection after the PCBAs completed. We would be glad to help on functional testing, users should provide detailed guidance and related tools for the test.

6. Lead Time

Elecrow provides the PCBA service speedy. The PCB will be completed in 3~5 days after your order confirmed, in the meanwhile, we will prepare the components. But note that if there are some components in your BOM that not popular used, we may need to import them aboard, it will cost 7~12 days. After the component ready, the soldering and testing will be completed in 1 week. With our fast logistic service, the shipping time could be 1~2 days for Japan and normal American, and 2~3 days for Europe.

7. Payment

Elecrow accept payment with Paypal/Credit Card. For payment more than $1,000, we also accept the wire transfer payment.

8. Package and Security

Elecrow package your products as your requirements. We will ship the PCBA with high quality packaging, to avoid damage in the shipping. We can package your project with ESD bags/ Bubble bags or personal requirements such as labels with your logo.

Elecrow promises not to disclose any of your design files, your related designs are safe in Elecrow. Elecrow can also assign NDA with customers to ensure the safety or your design.