All The 3D printer Extruder Basics You Should Know

All The 3D Printer Extruder Basics You Should Know

What is a 3D printer extruder?

The 3D printer extruder is a device that melts filaments (usually plastic) and extrudes them in a controlled manner to build a 3D printed object layer by layer. The 3D printer extruder is a critical component in the 3D printing process. It plays a very important role in determining the printed object's accuracy, speed, and quality.

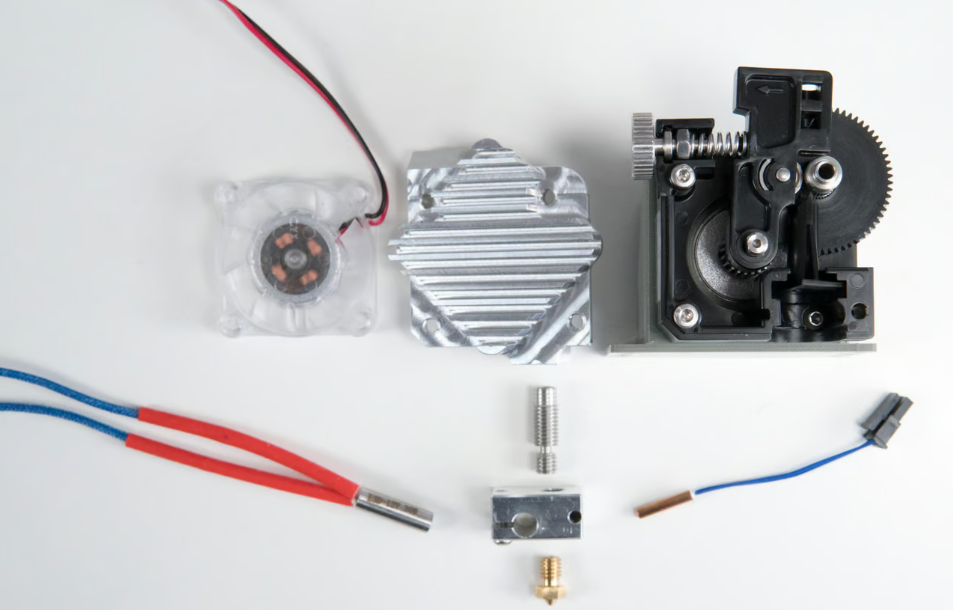

The 3D printer extruder typically consists of a stepper motor, a gear system, a heat sink, a hot end, nuts and bolts that hold it together, and a nozzle; all of these parts work together to push the filament through the hot end and onto the build platform.

Types of 3D printed Extruders

There are mainly 2 types of 3D printer extruders: Direct Drive Extruders and Bowden Extruders.

Usually, a traditional 3D printer extruder can only print one type of filament in the working time, but according to the increasing needs and higher demands for 3D printing, the dual extruder starts as an optimal choice for users who want to achieve mixed filament products.

Direct Drive Extruder

The direct drive 3D printer extruder is a type of extruder where the motor is mounted directly on the print head. This design provides greater control over the filament, which can result in more accurate and consistent prints. In a direct drive extruder, the filament is pushed directly into the nozzle by the extruder, which is advantageous for many reasons, but also has some drawbacks.

Bowden Extruder

The Bowden 3D printer extruder uses a long, flexible tube( a long PTFE hose called a Bowden) to guide the filament from the extruder motor to the hot end. The motor is located remotely from the hot end, which reduces the weight of the print head and allows for faster printing speeds. In contrast to a direct extrusion system, the extruder in a Bowden system is mounted on the frame of the printer.

Dual Extruder

An FDM-type dual extruder 3D printer uses two extruders to print different filament materials, which allows the user to build soluble support structures and produce multicolored objects.

Key Components of a 3D printer extruder

Hotend

A hot end is a component in an FDM 3D printer extruder that heats, melts, and extrudes layers of material through a nozzle. Providing optimal thermal dissipation as well as maintaining a consistent temperature and accurate temperature is the goal of the entire hot end structure.

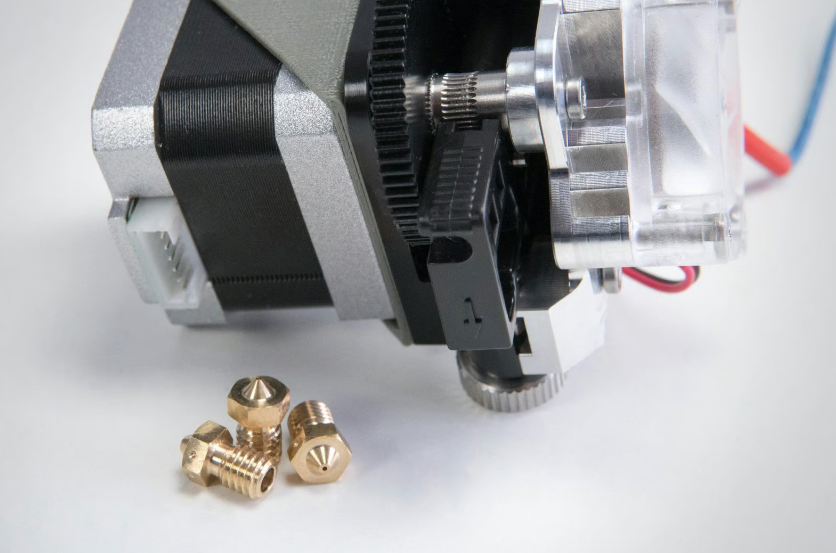

Nozzle

The 3D printer nozzle is a small component in the 3D printer extruder system that is responsible for extruding the molten filament material onto the print bed or onto previously printed layers. The nozzle is typically a small cylindrical tube that screws into the extruder assembly, with a small opening at the tip through which the melted filament is forced.

The size of the nozzle orifice can vary. Smaller orifices typically produce more detailed prints but take longer to print, and larger orifices produce faster but less detailed prints. Nozzles are typically made of brass, hardened steel, or other materials that can withstand high temperatures and wear from the abrasive nature of some filaments.

Filament Drive

The drive gear in most 3D printers grabs the filament and squeezes it between two bearings. The teeth on the drive gear bite into the filament, pushing it forward or backward depending on the direction the drive gear is spinning.

The filament drive typically consists of a motor, gear train, and small bearing or roller pushing the filament against the teeth. As the motor rotates, the gears pull the thread into the extruder and through the hot end, melting and extruding through the nozzle.

The filament drive is a critical component in a 3D printer extruder system because it determines the accuracy and consistency of extruded material and can affect the quality of the final printed object. There are several different types of filament drives, including direct drive extruders and Bowden cable extruders, which differ in the way they deliver the filament to the hot end and can affect the printing speed, accuracy, and the ability to print with flexible or high-strength materials.

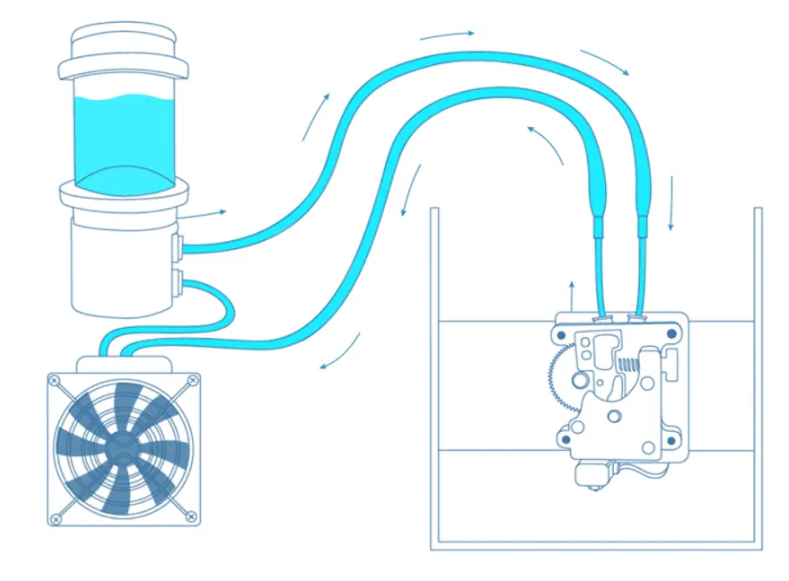

Cooling System

A 3D printer's extruder cooling system is an important component in improving print quality and preventing warping and other 3D printing problems. There are generally two types of cooling systems used in 3D printers:

Part cooling fans: A part cooling fan is a fan mounted on the print head or near the nozzle of the printer. Its primary purpose is to cool the printed part during the printing process, which helps prevent warping and improves print quality. The fan blows cool air onto the print part, which can also improve the accuracy of overhangs and bridges by solidifying the material before it has a chance to sag or drop.

Heat Sink Cooling: A heat sink cooling system is used to regulate the temperature of the hot end of the 3D printer. It typically consists of a heatsink mounted on the hot end that draws heat from the nozzle, and a fan that blows cool air over the heatsink to aid cooling. This helps prevent heat creep, which can cause the filament to melt prematurely and clog the nozzle.

A well-designed cooling system is critical to quality printing, especially when printing on warp-sensitive materials such as ABS or nylon. The cooling system can be controlled by the printer's firmware. The firmware adjusts the fan speed and other parameters based on the specific needs of the print job.

3D printer Extruder Thermistor

FDM 3D printer extruders utilize thermometers at several places. The hot end of the printer involves screwing the nozzle into a block of metal (often covered with silicone), which warms up and melts filament. There are two pairs of wires attached to this block, the first powering the heating element and the second allowing the temperature of the block to be measured precisely through a thermistor embedded in a space within the block.

3D printer thermistors of type 3950 100k are commonly found. The number after "NTC" describes the coefficients used to describe the shape of the temperature-resistance curve of a thermistor. The characteristic shape, whose three coefficients (a, b, and c) still bear their names, was established in the 1960s by the researchers Steinhart and Hart. They are often simplified to a single value, B or β, with a value usually between 3500 and 4500.

Final Words

Knowing all the basics about 3D printer extruders can make you better understand the working mechanism of 3D printing, if you are a keen 3D printer enthusiast and want to 3D print your ideas to real life, you can turn to Elecrow for its professional 3D printing service if you want to buy some 3D printing accessories, Elecrow is also a good choice for component sourcing if you want to mass produce your DIY 3D printing ideas to reality, Elecrow even offers Partner seller program to help you sell your products online.

Join Elecrow's Partner Seller Program to reap the benefits!